11

12

13

14

15

16

17

18

19

20

271

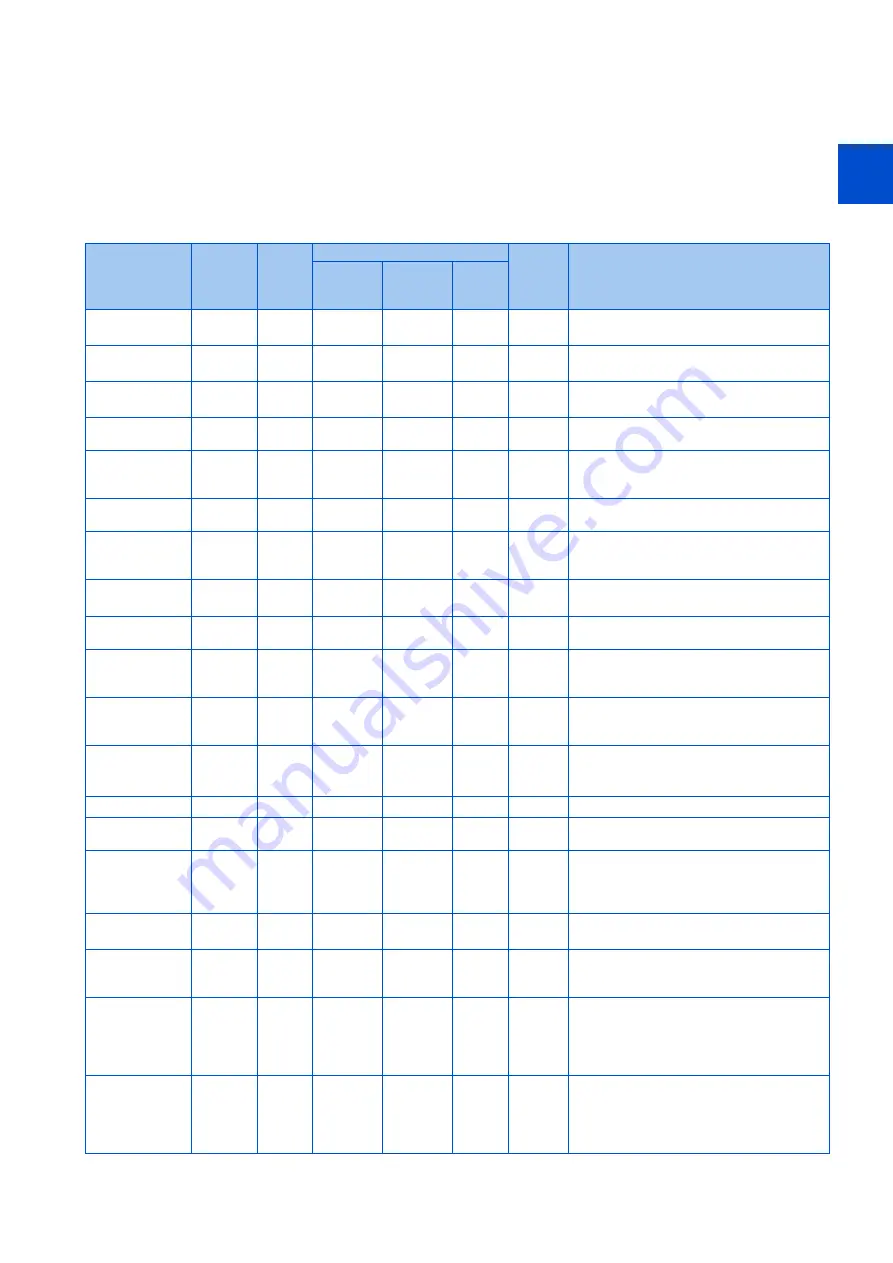

12. (M) Item and Output Signal for Monitoring

12.2 Monitor item selection on operation panel or via communication

Monitor item list (Pr.52, Pr.774 to Pr.776, Pr.992)

• Use

Pr.52, Pr.774 to Pr.776, or Pr.992

to select the monitor item to be displayed on the operation panel.

• Refer to the following table to find the setting value for each monitoring. The value in the Pr. setting column is set in each

of the parameters for monitoring (

Pr.52, Pr.774 to Pr.776,

and

Pr.992

) to determine the monitor item. The value in the

Communication column is the monitor code for communication. (The items marked with “—" cannot be selected. The circle

(

○

) in the Negative indication (-) column denotes that the monitored item can be indicated with minus sign during monitoring

via the communication option.

Monitor item

Incremen

t and unit

Pr.

setting

Communication

Negative

indicatio

n (-)

Description

Monitor

code 1

Monitor

code 2

Monitor

number

Output frequency

(speed)

1/0/100

H01

40201

1

○

The inverter output frequency is displayed.

Output

current

0.01 A

2/0/100

H02

40202

2

The inverter output current effective value is

displayed.

Output

voltage

0.1 V

3/0/100

H03

40203

3

The inverter output voltage is displayed.

Fault indication

—

0/100

—

—

—

Each of the last 10 faults is displayed

individually.

Set frequency /

motor speed

setting

H05

40205

5

The set frequency is displayed.

Operation speed

1 (r/min)

H06

40206

6

○

The motor speed is displayed (depending on the

Pr.53

setting). (Refer to

.)

Motor torque

0.1%

H07

40207

7

○

The motor torque is displayed as a percentage

(0% under V/F control), considering the rated

torque as 100%.

Converter output

voltage

0.1 V

H08

40208

8

The DC bus voltage value is displayed.

Regenerative

brake duty

0.1%

H09

40209

9

Brake duty set in

Pr.70

for the regeneration unit

set in

Pr.30

is displayed.

Electronic thermal

O/L relay load

factor

0.1%

10

H0A

40210

A

The motor thermal cumulative value is

displayed, considering the thermal operation

level as 100%.

Output current

peak value

0.01 A

11

H0B

40211

B

The peak value of output current, which is

constantly stored, is displayed. (It is reset with

every startup of the inverter.)

Converter output

voltage peak

value

0.1 V

12

H0C

40212

C

The DC bus voltage peak value, which is

constantly stored, is displayed. (It is reset with

every startup of the inverter.)

Input power

0.01 kW

13

H0D

40213

D

The power at the inverter input side is displayed.

Output power

0.01 kW

14

H0E

40214

E

The power at the inverter output side is

displayed.

Load meter

0.1%

17

H11

40217

11

Torque current is displayed as a percentage,

considering

Pr.56

setting value as 100%. (0% is

displayed under the control mode other than V/

F control.)

Motor excitation

current

0.01 A

18

H12

40218

12

The motor excitation current is displayed.

—

19

H13

40219

13

The position pulse of the encoder is displayed.

(The output voltage is displayed when a vector

control option is not installed.)

Cumulative

energization

time

1h

20

H14

40220

14

The cumulative energization time since the

inverter shipment is displayed. The number of

times an integrated value has reached the

maximum value of 65535 hours can be checked

in

Pr.563

.

Actual operation

time

1 h

23

H17

40223

17

The cumulative operation time is displayed. The

number of times an integrated value has

reached the maximum value of 65535 hours can

be checked in

Pr.564

. Use

Pr.171

to reset the

cumulative operation time. (Refer to

.)

Содержание FR-E800

Страница 17: ...16 1 Introduction 1 3 Related manuals MEMO ...

Страница 51: ...50 2 Basic Operation 2 8 I O terminal function assignment MEMO ...

Страница 89: ...88 3 Parameters 3 4 Parameter list by function group number MEMO ...

Страница 135: ...134 5 Speed Control 5 9 Troubleshooting in the speed control MEMO ...

Страница 153: ...152 6 Torque Control 6 7 Troubleshooting in torque control MEMO ...

Страница 195: ...194 8 E Environment Setting Parameters 8 18 Current average value monitor signal MEMO ...

Страница 237: ...236 10 D Operation Command and Frequency Command 10 6 Operation by multi speed setting MEMO ...

Страница 339: ...338 13 T Multi Function Input Terminal Parameters 13 9 Start signal operation selection MEMO ...

Страница 455: ...454 16 G Control Parameters 16 13 Speed smoothing control MEMO ...

Страница 481: ...480 18 Appendix 18 4 Parameters functions and instruction codes under different control methods MEMO ...