Page 13 (41)

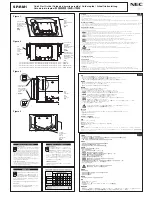

3: Use 10mm wrench to adjust position of the reveiver unit. (Version with upgraded purge air flow pictured).

Main alignment adjustment should be done from transmitters installationg flange as shown

on pictures 1 and 2.

As the laser beam is very compact, only small hol

es (10…50 mm dia) to get beam through,

are needed. Normally there is a small under pressure inside the stack, and outside air auto-

matically keeps the holes clean. In case there is overpressure in the stack, but source and re-

ceiver can be flange-mounted. Then, using the instrument-air purge system to slightly over-

come stack pressure keeps the instrument clean and functional.

The mounting system obviously varies from case to case. Basically there are three different

mounting systems:

a)

Mounting in the stack itself by L-type supports

b)

Mounting on the support structures (or on the floor/roof) around the stack. In this case

possible temperature related movement of the stack may require elliptical holes in the

stack.

c)

Mounting on the flanges welded in the stack. This case provides a solution, when

there is overpressure in the stack and gas escape from small holes is not allowed.

A specific problem appears when the dust content is very high. Then you might need to short-

en the laser path by horizontal tube inside the stack. As a rule of thumb, 1 m distance is

enough for concentrations 1-5 g/m

3

. Higher concentrations need shorter path.

Содержание LM 3188

Страница 24: ...Page 24 41 APPENDIX 1 Monitor Unit M 318 mech drawing ...

Страница 25: ...Page 25 41 APPENDIX 2 Receiver unit R318 mech drawing R318 Receiver unit 820 007 820 008 and 820 009 ...

Страница 26: ...Page 26 41 APPENDIX 3 Receiver unit R318 mech drawing R318 Receiver unit 820 005 and 820 006 ...

Страница 27: ...Page 27 41 APPENDIX 4 Receiver unit R318 mech drawing R318 Receiver unit 820 002 820 003 and 820 004 ...

Страница 28: ...Page 28 41 APPENDIX 5 Receiver unit R318 mech drawing R318 Receiver unit 820 000 and 820 001 ...

Страница 29: ...Page 29 41 APPENDIX 6 Transmitter unit L318 mech drawing L318 Transmitter unit 830 005 ...

Страница 30: ...Page 30 41 APPENDIX 7 Transmitter unit L318 mech drawing L318 Transmitter unit 830 003 and 830 004 ...

Страница 31: ...Page 31 41 APPENDIX 8 Transmitter unit L318 mech drawing L318 Transmitter unit 830 001 and 830 002 ...

Страница 32: ...Page 32 41 APPENDIX 9 Laser Unit L 318 PCB layout ...

Страница 33: ...Page 33 41 APPENDIX 10 Receiver unit R 318 PCB layout ...

Страница 34: ...Page 34 41 APPENDIX 11 LM 3188 Wiring ...

Страница 35: ...Page 35 41 APPENDIX 12 LM 3188 Wiring universal power option ...

Страница 36: ...Page 36 41 APPENDIX 13 Monitor Unit test points and jumpers ...

Страница 37: ...Page 37 41 APPENDIX 14 Monitor Unit Options ...

Страница 38: ...Page 38 41 APPENDIX 15 Installation examples ...

Страница 41: ...Page 41 41 APPENDIX 18 Mating flange adapters ...