41

MM-PCM Series

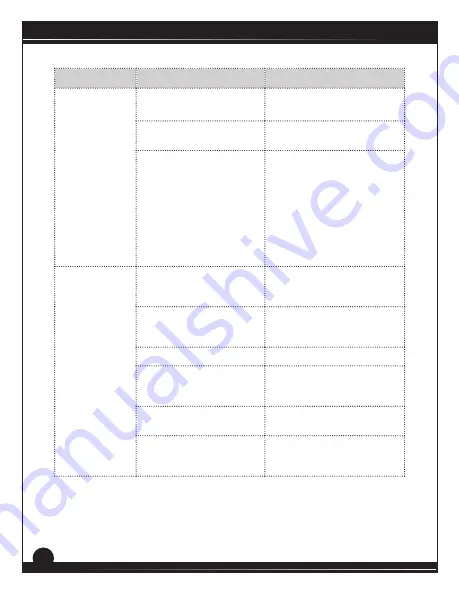

PROBLEM

POSSIBLE CAUSE

SUGGESTED SOLUTIONS

Line fuse

blows.

1. Line fuse is the wrong size.

1. Check that the line fuse is

correct for the motor size.

2. Motor cable or armature is

shorted to ground.

2. Check motor cable and

armature for shorts.

3. Nuisance tripping caused by

a combination of ambient

conditions and high-current

spikes (i.e. reversing).

3. Add a blower to cool the

drive components, decrease

TORQUE LIMIT settings, resize

motor and drive for actual

load demand, or check for

incorrectly aligned mechanical

components or “jams”. See

page 27 for information on

adjusting the TORQUE LIMIT

trim pot.

Line fuse does

not blow, but

the motor does

not run.

1. Speed adjust potentiometer

or input voltage signal is set

to zero speed.

1. Increase the speed adjust

potentiometer setting or input

voltage or current signal.

2. INHIBIT mode is active.

2. Add a short between terminals

3 and 4 and remove any short

between terminals 4 and 5.

3. S2 is shorted to S1.

3. Remove the short.

4. Drive is in current limit.

4. Verify that the motor is not

jammed. Increase TORQUE

LIMIT setting if set too low.

5. Drive is not receiving AC line

voltage.

5. Apply AC line voltage.

6. Motor is not connected.

6. Remove power. Connect the

motor to A1 and A2. Reapply

power.