Miller SRL2-M Series

Rodless Cylinders

26

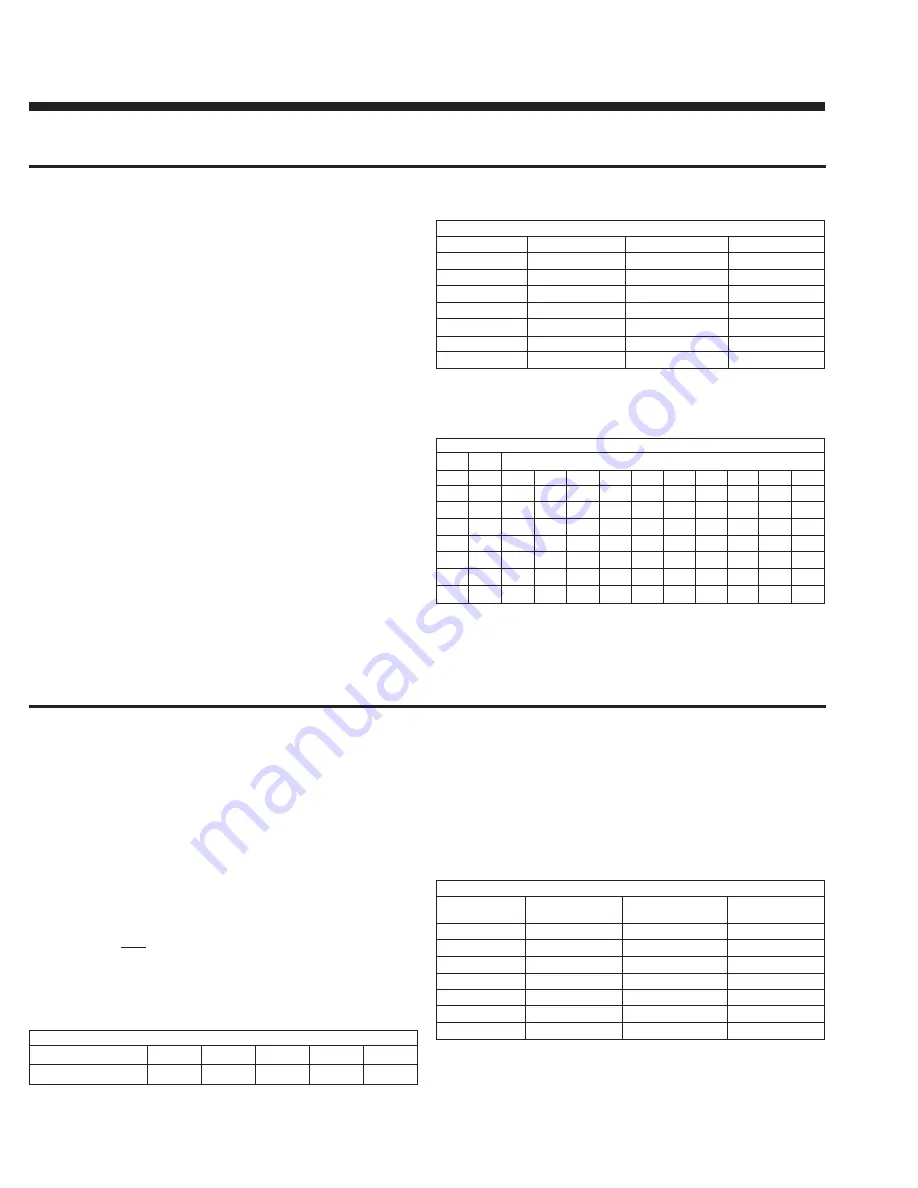

Moment Friction Factor

Bore mm

C1

C2

C3

16

.18

.61

.18

20

.15

.53

.15

25

.13

.41

.13

32

.10

.33

.10

40

.10

.28

.10

50

.10

.23

.10

63

.08

.20

.08

Figure 12

Maximum Kinetic Energy [E] Absorption

Bore

Cushion

With Cushion

W/out Cushion

length in.

in.- lbs.

in.-lbs.

16

0.75

1.95

0.06

20

0.87

5.22

0.09

25

0.82

12.39

0.13

32

0.92

22.75

0.27

40

0.94

37.79

0.44

50

0.98

80.81

0.64

63

1.16

154.01

1.22

Figure 15

Figure 14

Figure 13

Load Factor and Forces

The Load Factor must be determined to ensure that the cylinder force

available is adequate to overcome the total resistive force plus the

additional friction caused by the load moments. This is done by

calculating the frictional forces (Ff) created by the moments and the

weight, using the formulas and the chart in Figure 12, and adding the

resistive force (Fx), which is determined by the actual application.

Ff 1 = M1 x C1

Ff 2 = M2 x C2

Ff 3 = M3 x C3

Fwf (Weight Frictional Force) = .2 x (W

T

)

The sum of all resistive forces (F) including friction is determined as

follows:

Horizontal Mountings:

F = Ff1 + Ff2 + Ff3 + Fwf + Fx

Vertical Mountings:

F = Ff1 + Ff2 + Ff3 + W

T

+ Fx

Actual Cylinder Force (Fa) available is shown in Figure 13.

Load Factor (LF) is determined as follows:

%LF = F/Fa x 100

Load Factor (LF) should never exceed 50%. If LF does exceed 50%, it

will be necessary to select the next larger bore size and calculate its

load factor.

Deceleration and Energy Absorption

Actual Cylinder Force (Fa) in Lbs.

Effective

Pressure PSI

Area

Bore Sq.In. 15

20

30

40

50

60

70

80

90

100

16

0.33

—

—

6

10

13

16

19

22

25

28

20

0.48

—

7

11

15

20

24

28

33

37

41

25

0.84

—

11

19

26

34

41

49

56

64

71

32

1.26

—

17

28

39

50

62

73

84

95

107

40

1.96

—

27

44

61

78

97

114

131

148

166

50

3.08

35

42

69

96

123

152

179

206

233

260

63

4.86

55

66

109

152

194

239

283

325

368

411

Load Factor Coefficient

Load Factor

10%

20%

30%

40%

50%

K

1.15

1.30

1.45

1.60

1.75

The kinetic energy (E) to be absorbed during deceleration must be

calculated to determine whether the cushion can absorb the load or an

external shock absorber may be required. To calculate this, first

determine the actual speed (V) at which the piston enters the cushion by

multiplying the load factor coefficient (K), from Figure 14, times the

average speed (V1) that the piston travels. V1 is derived from actual

cycle time determined by the application requirement.

The formula is as follows:

V (In. per Sec.) = KV1

E (In.-Lbs.)

= W

T

V

2

772

The following chart, Figure 15 shows the maximum energy absorption

for each size cylinder, both with cushions and without cushions. If the

requirements for your application fall below the number shown for the

size of the cylinder you have selected, then no external shock absorber

may be required, but inertia forces and moments should be considered.

www.comoso.com