7

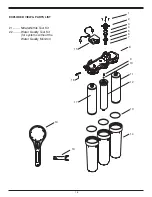

B. Tools Recommended for Installation

The following tools will cover most of the

installation sites encountered:

1.

3

/

8

" variable speed electric drill.

2. Extension work light with outlet.

3. Safety glasses.

4. 1¼" porcelain hole cutter kit.

5. 1¼" Greenlee hole punch and

1

/

8

" and

½" metal drill bits for pilot hole.

6. Center punch and hammer.

7. 1¼" wood bit.

8. Concrete drill bits.

9. Assorted wood and metal drill bits including

7

/

32

" metal drill bit.

10. Phillips head and flat blade screwdrivers.

11. ½",

9

/

16

" and

5

/

8

" open end wrenches.

12. 10" Crescent wrench with jaws taped to hold

faucet.

13. Basin wrench or 10" pipe wrench.

14. Teflon tape.

15. Wide masking tape or duct tape.

16. Plastic tubing cutter.

17. Extra plastic tubing.

18. Low range air pressure gauge.

19. Bicycle hand air pump.

20. Small bottle of liquid chlorine bleach.

21. Graduated measuring cylinder.

22. Paper towels, wisk broom and assorted clean

up materials.

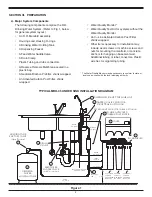

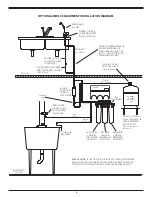

C. Site Selection for Major System Components

The R.O. System was designed to fit under a

sink, however, because of space limitations

or other reasons, the system’s flexible design

allows for other locations. When determining the

location remember that access to a cold water

tap line, the household drain, and ease of filter

replacement are important considerations.

All components and tubing should be located in

an area not exposed to freezing temperatures. If

winter temperatures are severe, the area should

be above the minimum temperature listed in

Table B for proper performance. Do not expose

unit or tubing to direct sunlight.

1. Dispensing Faucet–

The faucet should be

placed near the sink where drinking water

is normally obtained. Convenience of use

(filling of water pitchers and glasses), and an

open area beneath the faucet under the sink

for attaching product and drain tubing are

considerations. A 2" diameter flat surface is

required above and below the installation site.

The thickness of the mounting surface should

not exceed 1¼". Watch for strengthening

webbing on the underside of cast iron sinks.

2. Drinking Water Holding Tank–

The Holding

Tank may be placed where it is convenient

within 10 feet of the faucet; under the sink or

in an adjacent cabinet are best the choices.

If a longer run of tubing is required, the

tubing should be the

3

/

8

" diameter OD size

to prevent a high pressure drop. Remember,

these tanks can weigh up to 30 pounds when

full of water; a firm, level area is required.

3. R.O. Manifold Assembly–

The manifold can

be installed on either the right or left side

of the under–sink area or a cabinet. The

right side is recommended because all the

tubing will be to the back of the cabinet and

out of the way. Installation in the basement

is also an option; one location is near the

laundry/utility sink where cold potable water

and drain access are handy. The mounting

location should allow adequate clearance

and accessibility for cartridge changes.

4. Feed Water Connection–

The Feed Water

Saddle Valve should be located as close to

the manifold assembly as possible. USE A

POTABLE COLD WATER SUPPLY ONLY.

Softened water is preferred as it will extend

the life of the R.O. Membrane.

5. Drain Connection–

The waste water must

go to drain through an anti–siphon air gap.

The air gap is provided for in the base of

the faucet. If discharging into a utility sink

or standpipe, an air gap of greater than 1"

above the flood rim must be provided.

Do NOT connect the system drain line to

the dishwasher drain or near the garbage

disposal. Backpressure from these units may

cause the air gap to overflow.

Содержание MRO-35

Страница 15: ...15 NOTES ...