Operator's Manual: Millcreek

6700P &

8700P PTO Spreaders

Procedures for Spreader Adjustment (continued)

Adjusting the Drive Chains

NOTE:

The drive chains are factory-set for the proper operating tension and should not require adjustment.

The following instructions are provided for reference only, in rare cases where re-adjustment orrep lacement

may become necessary.

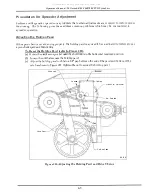

Refer to Figure 4B

on the previous page for an illustration of the drive chains and related components. The

chains should be snug, but not too tight.

If

the chains are too tight, they may cause excessive wear on the

bushings in the crank arm sprocket (resulting in premature failure).

If

the chains are too loose, they can slip and

jump sprocketteeth when the spreader is operating with a full load.

•

Check the

drive chains in two positions:

( a)

Gearbox to

Beater Chain:

check the bottom span.

(b)

Ratchet Drive Chain:

check top or bottom span.

NOTE:

Whenpushingonthemiddleofthespanwithonefinger(about20lbs.pressure),

the chain should deflect about 3/8 to 1/2 inch. A straight-edge ruler maybe helpful in

verifyingthepropersetting.

•

Adjust the

drive chains

according to Figure 4B and the following guidelines:

( a)

Gearbox to Beater Chain:

adjust the

idler sprocket

as indicated.

(b)

Ratchet Drive Chain:

adjust the

bracket position

by loosening the two (2) 1/2"

bracket bolts and sliding the bracket forward or backward as shown.

4-4

All manuals and user guides at all-guides.com