Operator's

Manual: Millcreek 6700P & 8700P PTO

Spreaders

SECTION 3:

OPERATION

Understanding Spreader Operation

Proper and safe operation of the Millcreek 6700P /8700P Spreader requires: (1)being familiar with the

spreader's operating components and (2) heeding all safetyprecautions as stated in this manual.

The Spreader

Operating Components

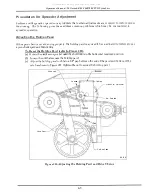

By definition, the left and right sides of the spreader are determined while sitting on the tractor seat. PTO model

spreaders are powered through the tractor drive train. The PTO powers the apron chain and the beater. For

furtheriuformation on engaging the PTO drive line, please refer to the following section,

Operating the

Spreader.

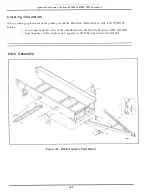

Guidelines for Loading the Spreader

for Operation

•

Millcreek recommends that you

load the spreader from

the front

toward the back

to

facilitate easier unloading.

•

ATTENTION:

NEVER store manure in the spreader between unloading times during

critical cold weather months when a frozen load could result in severe equipment damage

(i.e. tom floor apron chain).

•

DO NOT store wet manure in the spreader (or keep the spreader outdoors with manure in it)-

doing so will accelerate rusting of the steel.

Operating the Spreader

WARNING! Before proceeding with operation of the spreader, review all safety

statements as provided in Section 1 of this manual.

6

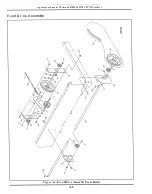

1.

2.

3.

4.

5.

WARNING:

To prevent serious personal injury, ensure that ALL safety shields are in place on the

spreader before starting operation. NEVER operate the spreader without ALL safety shields in place.

If

you have a spreader with the end gate option, lift the end gate.

With the tractor at idle, simply activate the switch to engage the PTO.

NOTE:

For older tractor models, you may need to decompress the clutch and activate the tractor

PTO lever. Release the clutch slowly so the PTO shaft will start the spreader apron chain and beaters.

For best results, run the tractor throttle at the 540rpm PTO shaft speed and regulate the ground

speed to no more than 6 mph.

When the spreader box is empty, stop the PTO by disengaging the lever/switch on the tractor. Lower

the endgate (ifapplicable ).

Refer to Section 4 in this manual for maintenance to be performed following operation of the

spreader.

IMPORTANT! Be aware that it may be necessary to re-tighten bolts after a few hours of initial

operation -- watch and listen for any loose components. Be sure to check the wheel bolts for proper

torque (75-80

ft.

lbs.)

3-1

All manuals and user guides at all-guides.com

all-guides.com