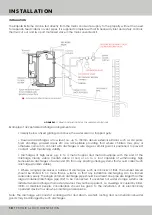

OVERVIEW

TECHNICAL DOCUMENTATION

07

DESCRIPTION

The Mikrofill Rapide Extreme is a domestic hot water generator that combines the advantages of both an

instantaneous water heater and a storage system, whilst ensuring that the associated boiler plant operates at

its optimum efficiency during domestic hot water generation. The Rapide Extreme is suitable for open vented

or unvented applications. Based on a stainless steel storage vessel the unit utilises a stainless steel plate heat

exchanger to “load” the vessel with water at a minimum of 60°C, during hot water demand the plate heat

exchanger effectively delivers hot water directly to the outlets, so “heat up” is reduced to minutes and

“recovery time” is a thing of the past. The Rapide Extreme does not rely on convection within the vessel to

transfer heat, the loading system introduces water at 60°C in to the top of the vessel. This drastically reduces

the proliferation of Legionella bacilli, and in instances where the associated boiler is of the condensing type,

the boiler will remain in condensing mode throughout domestic hot water generation; a situation that is

unattainable using conventional coil type hot water cylinders.The Rapide Extreme is supplied fully assembled,

prewired and inclusive of loading pump and electronic controller, advanced insulation ensures standing

losses are reduced to a minimum. The anode free stainless steel vessel carries a 30 year guarantee, whilst

maintenance is minimal.

Advantages

Domestic hot water available at all times

Very high flow rates available

Generates full cylinder of water at 60°C

Reduces legionella risk

Optimises boiler operation

Simple installation

Low maintenance

Low standing losses

30 year guarantee on cylinder

Short payback period