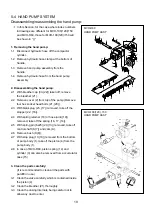

1.

2.

3.

4.

5.

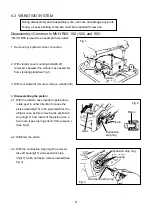

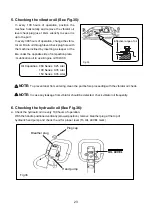

Insert 210

o

cam ring(7) to drive shaft(4). Pay

attention to the direction of flange face to

install.(See Fig.18)

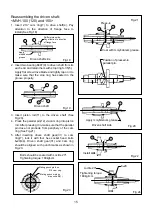

Insert two bearing 6807(9) to driven shaft from its

each end and retain them with stop ring S-35(5).

Apply flat screw drive blade and lightly tap on it to

make sure that the stop ring has seated in the

groove properly.

Insert piston rod(11) to the driven shaft (See

Fig.20).

Press the parallel pin(12) via cam ring into piston

rod. After pressing it in,make sure that the parallel

pin dose not protrude from periphery of the cam

ring.(See Fig.21)

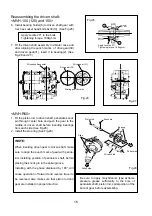

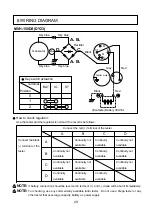

After inserting driven shaft gear(31) to cam

ring(7), lock it with four hex socket head bolts

6

x

20(44). Driven shaft gear(31) and cam ring

should be aligned with punch marks as shown in

Fig.23.

Bolts should be coated with Loctite 271.

Tightening torque: 180kgf-cm

Reassembling the driven shaft:

<MVH-100 (120) and 150>

15

Fig.20

Fig.22

Fig.24

Fig.23

Fig.21

Driven shaft side

Mating punch mark on

210

o

cam ring

Mating punch mark on

driven shaft(31)

Loctite 271

Tightening torque:

180kgf-cm

6

x

20

Install

Apply molybdenum grease.

Press-in

4

7

12

4

11

Shifter piston side.

Pay attention to direction

of flange face.

Fig.18

Driven shaft side

Apply

molybdenum

grease

4

7

Coat with molybdenum grease.

Position of pressed-in

parallel pin.

Fig.19

Driven shaft

4

5

5

7

9

9

31

7

Содержание MVH-R100

Страница 1: ...410 00801 MVH R60 100 120 150 SERVICE MANUAL REVERSIBLE SOIL COMPACTOR R...

Страница 32: ......