The fuel filter is installed at the bottom of fuel

tank, should rammer be laid down dirt from

fuel filter may invade into injection nozzle and

fuel pump causing damage.

7-9 Storage

* When storing the rammer for long periods of

time, thoroughly drain all fuel from fuel line.

* Clean exterior of rammer with an oil-moistened

cloth. Cover and store in a clean, dry place.

7-4-3 The interval of oil replacement

INITIAL OIL CHANGE:

After 20 hours of operation

SECOND OIL CHANGE ANDIOR LATER:

Every 100 hours of operation

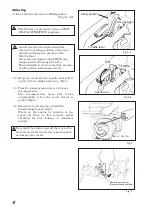

7-5 Cleaning the Air Cleaner

Cleaning the Air Cleaner (every 200

-

300

hours) (Fig. 9)

* Remove element from pre-cleaner at the top

of crankcase(body side).

* Wash the element (outside) in detergent

solution.

* Shake out excess moisture and dry the

element.

* Clean inside element with air from the inside

of element.

7-6 Cleaning the Oil Filter

Drain oil filter every 100 hours of operation.

Replace the oil filter every 1,000 hours of

operation. (Fig.10)

7-7 Fuel Pipe & Oil Pipe

* Check fuel line regularly for damage, paying

attention to clamps to assure a tight fit.

* Replace fuel line every two years to maintain

original performance.

7-8 Transportation

Maintain upright position of rammer at all

times.

Transport rammer in upright position.

If machine must be laid down for

transportation, drain the diesel fuel first and

lay machine with muffler side down. (Fig.11)

Outer element

Inner element

Fig.9

Oil filter

Fig.10

Lay machine with

muffler side down

after draining the

diesel fuel.

Fig.11

11

Содержание MT-76D

Страница 2: ......

Страница 18: ...Note...

Страница 19: ......

Страница 20: ...PRINTED IN JAPAN MIKASA SANGYO CO LTD 1 4 3 Sarugakucho Chiyoda ku Tokyo 101 0064 Japan...