Installation

Electric installation and device termination shall be

done by qualified persons only, by respecting the VDE

specifications and local regulations.

1. Power down the equipment.

2. Strip the wire by 7 mm, put on the end sleeve, insert to

terminal body and tighten the terminal screw with a screwdriver.

Wire cross section:

0.5 mm² - 4 mm² solid wire or

0.5 mm² - 2.5 mm² stranded wire with end sleeve

3. Device connection per wiring diagram.

Mounting

On standard DIN rail per DIN EN 50022 (35 x 7.5 mm), in junction

boxes and/or on distribution panels.

reset push button

3

2

1

5

4

Installation indications

G

Do not invert contacts L1 and LM (wrong current direction =>

device is permanently in the alarm mode)

G

Measuring current can be exceeded by max.

10 %, for higher motor current use a suitable current transfor-

mer.

G

If a current transformer is used, observe the

current direction (do not invert k and l!).

The

connection L1 on the secondary winding is

mandatory. The CPW is not able to measure without this con-

nection as current cannot flow towards L2 or L3. To measure

the cosj (phase shift difference between current and voltage)

voltage has to be applied at L1.

G

If the current falls below the measuring value

(1 A or 0.2 A) the CPW signals alarm.

G

If a frequency converter is used it is mandatory to install the

CPW behind the frequency converter. It is not possible to mea-

sure a reliable cos

ϕ

before the frequency converter.

Device Settings

G

turn the rotary time switch (3) to the left

G

turn the rotary cosj switch (5) to the right

G

install a bridge between S1 and S3 (error memory switched-off)

G

switch the motor on and let it run at its lowest speed => red

LED (2) is lighting

G

turn the rotary cosj switch (5) slowly to the left, until the relay

responds and the red LED turns off.

RPM-regulated motors (e.g. with frequency converter or delta-wye

connection) should run through all speeds to provide for reliable

operation. Check also functioning of bypass connections. Test

shut-down by error simulation (take off v-belt or check a pump

under dry running conditions).

When tests are finished install the bridges (error memory push-

button etc.), integrate the relay contacts into the malfunction

indication and set the required time.

Function settings by bridges S1, S2, S3

S1 - S2 open

relay released at underload

S1 - S2 bridged

relay activated at derating

S1 - S3 open

with error memory

S1 - S3 bridged

without error memory

With activated error memory (no bridge over S1-S3) the error

signal remains displayed until it is acknowledged or the operation

voltage is interrupted.

A NO contact at S1 - S3 allows a remote reset of the module.

7 mm

Display and Operation

green LED - operating voltage

indication

red LED - error indication

rotary switch for time setting

rotary switch for cos

ϕ

setting

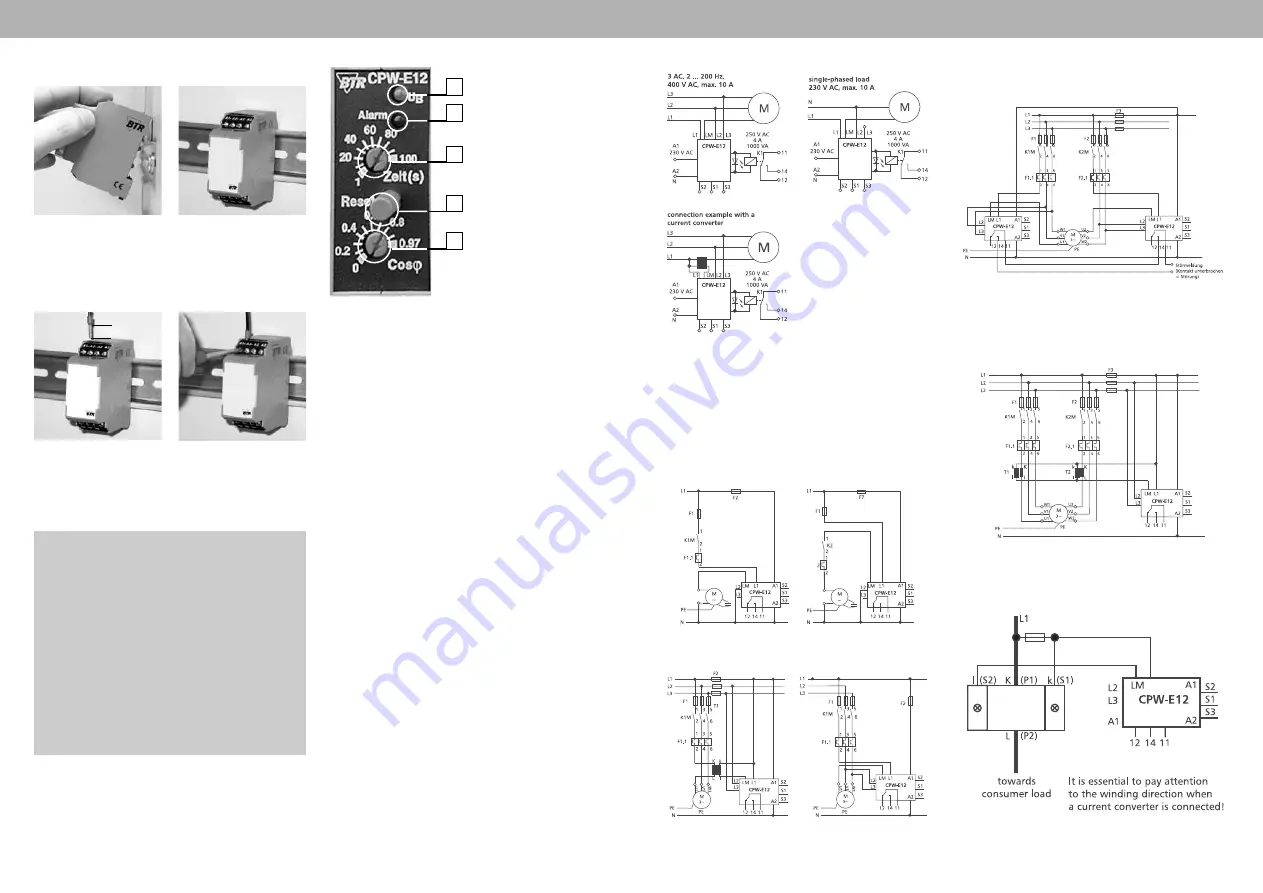

Wiring Diagrams

Connection Examples

Important!

It is essential to consider the wiring diagram of the current con-

verter for the different connection examples!

Pay attention to the minimum current at the CPW-E12!

Connection to Single Phase Motors

Connection to Three Phase Motors

Connection Examples

Wiring Diagram for Current Converter

Connection to Two-stage Motors with

Separate Windings and Current Converter

Connection to Two-stage Motors with

Separate Windings