30

PRM FH | Version 1.04 | EN

Maintenance, servicing and repair

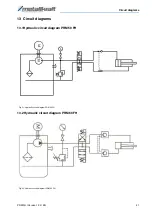

10.1Hydraulic system

The hydraulic pressure has been set at the factory.

The hydraulic pressure value should not be changed!

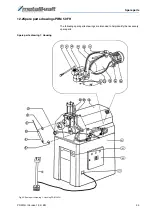

Fig. 23: Hydraulic pressure

To adjust the pressure, turn the lock nut slightly loosely (counterclockwise).

Clockwise rotation increases the pressure, counterclockwise rotation decrea-

ses the pressure. After setting the desired pressure, retighten the lock nut.

Check the oil level of the hydraulic system regularly and top up wit hydraulic oil

if necessary.

The gearbox for the roller drive is also maintenance-free. However, a monthly

check of the hydraulic system and hydraulic cylinders for leaks is recommen-

ded. The cover must be removed for this purpose.

NOTE!

After care, maintenance and repair work, check that all

covers and protective devices have been properly fitted to

the machine again and that no tools are left inside the

machine or in its working area.

Damaged protective devices and equipment parts must be

repaired or replaced by customer service or a specialist

workshop.

ATTENTION!

During transport of the machine or when the machine is

switched to the horizontal working position for the first time,

some excess oil may leak from the tank. This will not affect

the operation of the machine.

Содержание PRM 50 FH

Страница 1: ...PRM 50 FH Operating Instructions PRM 50 FH Ring Bending Machine hydraulic PRM 60 FH...

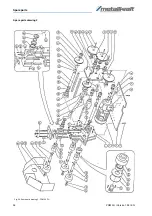

Страница 36: ...36 PRM FH Version 1 04 EN Spare parts Fig 26 Spare parts drawing 2 PRM 50 FH Spare parts drawing 2...

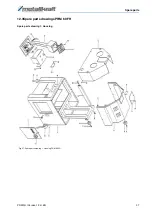

Страница 38: ...38 PRM FH Version 1 04 EN Spare parts Spare pars drawing 2 Fig 28 Spare parts drawing 2 PRM 60 FH...

Страница 39: ...Spare parts PRM FH Version 1 04 EN 39 Spare parts drawing 3 Fig 29 Spare parts drawing 3 PRM 60 FH...

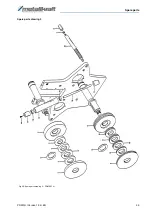

Страница 40: ...40 PRM FH Version 1 04 EN Spare parts Spare parts drawing 4 Fig 30 Spare parts drawing 4 PRM 60 FH...

Страница 49: ...Notes PRM FH Version 1 04 EN 49 15 Notes...

Страница 50: ...www metallkraft de...