Safety

KRBS 101 | Version 1.03

5

Operator:

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behaviour. Any tasks which need to be per

-

formed beyond the operation in the standard mode must

only be performed by the operator if it is indicated in

these instructions and if the operating company expres

-

sively commissioned the operator.

Electrical specialist:

Due to his professional training, knowledge and experi

-

ence as well as his knowledge of respective standards

and regulations the electrical specialist is able to perform

works on the electrical system and to recognise and

avoid any possible dangers himself.

Specialist staff:

Due to their professional training, knowledge and experi

-

ence as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them

-

selves.

Manufacturer:

Certain works may only be performed by specialist per

-

sonnel of the manufacturer. Other personnel is not au

-

thorized to perform these works. Please contact our cus

-

tomer service for the execution of all arising work.

2.4 Personal protective equipment

The personal protective equipment serves to protect per

-

sons against impairments of safety and health while

working. The staff has to wear personal protective equip

-

ment while performing different works on and with the

Machine which are indicated in the individual paragraphs

of these instructions.

The personal protective equipment is explained in the

following paragraph:

2.5 Safety equipment

To protect against flying sparks on the housing above

the contact wheel, a protective screen attached. The on-

off switch unit is combined with an emergency stop

switch.

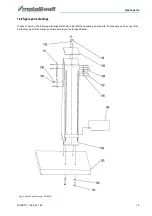

2.6 Safety signs on the machine

The following safety signs and notes are applied on the

Combined pipe, section and belt grinding Machine (Fig.

1), which need to be observed and followed.

Fig. 1: Safety signs

Eye protection

The protective goggles protect the eyes against parts

flying off and splashes of liquids.

Ear protection

The hearing protection protects the ears against

damages of hearing due to noise.

Breathing protection

The breathing protection serves for protecting the

respiratory passages and the lung against the intake

of dust particles.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric

-

tion, abrasions or deep injuries.

Safety boots

The safety boots protect the feet against crushes,

falling parts and slipping over on slippery under

-

ground.

Protective clothes

The protective clothes are tight clothes of little ten

-

sile strength.

1

2

3

5

4

Содержание KRBS 101

Страница 1: ...KRBS 101 Instruction Manual KRBS 101 KRBS 101 Combined pipe section and belt grinding machine...

Страница 20: ...20 KRBS 101 Version 1 03 Spare parts Fig 24 Spare Parts Drawing 2 KRBS 101...

Страница 21: ...Spare parts KRBS 101 Version 1 03 21 Fig 25 Spare Parts Drawing 3 KRBS 101...

Страница 22: ...22 KRBS 101 Version 1 03 Spare parts Fig 26 Spare Parts Drawing 4 KRBS 101...

Страница 23: ...Wiring Diagram KRBS 101 Version 1 03 23 13 Wiring Diagram Fig 27 Wiring Diagram KRBS 101...

Страница 25: ...Notes KRBS 101 Version 1 03 25 15 Notes...

Страница 26: ...www metallkraft de...