28

12.11

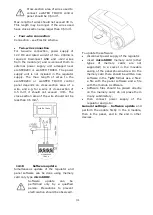

Connection of boiler's room

thermostat

Note: the boiler room thermostat

should be switched off if the whole

central heating system of the

building is supplied through a mixing

valve equipped with electric servo.

The regulator may work with mechanical or

electronic room thermostat, which opens the

contacts once the preset temperature has

been achieved.

Set-up the operation of room thermostat in:

Boiler settings

Room thermostat

Thermostat selection

Universal

Once the preset room temperature

has been reached, thermostat opens

its contacts and the display shows:

.

Once the temperature in the room, in which

the room thermostat is installed, has reached

the preset value, regulator reduces the

preset boiler temperature by the value set in

Inc. p. b. temp. thermostat and the display

shows

. This will cause longer breaks in

boiler operation (the boiler will remain in

SUPERVISION mode) and the same,

temperature in heated rooms will drop.

Moreover, the boiler pump (CH pump) may

be interlocked for a certain time by opening

the contacts of the room thermostat in

heated rooms. To activate this function -

enter:

Boiler settings

→

Room thermostat

→

CH pump standstill

and set the value of this parameter >0.

Setting the value of e.g. ,,5” causes the

pump will be stopped by the room

thermostat for 5 min. When ,,0” is set, the

CH pump will not be stopped by the room

thermostat. Once this time has elapsed, the

regulator switches on CH pump for a time set

in CH pump op t. th. on e.g. 30s. This

feature prevents from excessive cooling of

the system caused by a pump stop.

The pump interlock by opening

the

contacts

of

the

room

thermostat may be activated only

upon making sure the boiler will

not be overheated.

12.12

Connection of reserve boiler

The regulator can control a reserve boiler

(gas- or oil-), eliminating the necessity of

enabling or disabling this boiler manually.

The reserve boiler will be enabled if the

temperature of the pellet boiler drops, and

disabled when the pellet boiler reaches an

appropriate temperature. Connection to a

reserve boiler, e.g. oil-boiler one, should only

be made by a qualified fitter, in accordance

with the technical documentation of this

boiler.

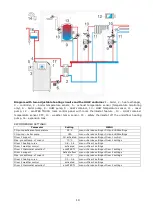

The reserve boiler should be connected via

relay to terminals 43-44 (Output H).

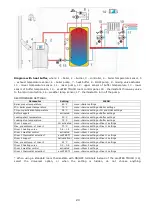

Model diagram of layout for connecting a reserve

boiler to the regulator, where: 1- regulator, 2 –

reserve boiler (gas- or oil-), 3 – module U3,

consisting of relay RM 84-2012-35-1012 and base

GZT80 RELPOL.

In a standard version, the regulator is not

equipped with the U3 module.

It should to perform assembly and

installation of the module by

yourself, in conformity with the

applicable standards.

Set the temperatures of reserve boiler switch

on/off:

Service settings

Boiler settings

Reserve boiler

Reserve boiler

Reserve boiler activation temp.

Control of reserve boiler is off upon setting

this parameter at ,,0”.

Then should set the support for output H for

reserve boiler:

Service settings

Output H = Reserve

boiler

Once the boiler has been fired up, and its

temperature has exceeded the preset value

(e.g. 25

C), regulator switches off the

reserve boiler and applies voltage 12V DC at

output H, which causes release of coil of U3

module relay and opening its contacts. Once

the boiler temperature has dropped below

Содержание ecoMAX860P TOUCH

Страница 2: ......

Страница 6: ...6...

Страница 7: ...INSTRUCTION MANUAL ecoMAX 860P TOUCH...

Страница 17: ...INSTALLATION AND SERVICE SETTINGS ecoMAX 860P TOUCH...

Страница 43: ......