90-823224--2 796

454 CID (7.4L) / 502 CID (8.2L) - 3A-53

Installation

IMPORTANT: Cylinder bores must be clean be-

fore piston installation. Clean with a light honing,

as necessary. Then clean with hot water and de-

tergent wash. After cleaning, swab bores several

times with light engine oil and clean cloth, then

wipe with a clean dry cloth.

1. Lubricate connecting rod bearings and install in

rods and rod caps.

2. Lightly coat pistons, rings and cylinder walls with

light engine oil.

3. With bearing caps removed, install connecting

rod bolt guide (3/8-24, use tool J-5239 or 7/16-20,

use tool J-35228) on connecting rod bolts.

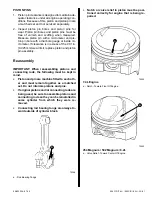

IMPORTANT: Be sure ring gaps are properly posi-

tioned as shown.

72373

b

c

d

a

a

d

b

c

b

b

2

3

1

Ring Gap Location

1 - Port Side

2 - Engine Front

3 - Starboard Side

a - Oil Ring Spacer Gap (Tang In Hole Or Slot Within Arc)

b - Oil Ring Gaps

c - 2nd Compression Ring Gap

d - Top Compression Ring Gap

4. Install each connecting rod and piston assembly

in its respective bore. Install with connecting rod

bearing tangs toward outside of cylinder block.

Use piston ring compressor to compress rings.

Guide connecting rod into place on crankshaft

journal with connecting rod bolt guide. Use a

hammer handle with light blows to install piston

into bore. Hold ring compressor firmly against

cylinder block until all piston rings have entered

cylinder bore.

IMPORTANT: Be sure to install new pistons in

same cylinders for which they were fitted, and

used pistons in same cylinder from which they

were removed. Each connecting rod and bearing

cap should be marked, beginning at front of en-

gine (1, 3, 5 and 7 in left bank and 2, 4, 6 and 8 in

right bank). Numbers on connecting rod and

bearing cap must be on same side when installed

in cylinder bore. If a connecting rod is ever trans-

posed from one block or cylinder to another, new

bearings should be fitted and connecting rod

should be numbered to correspond with new cyl-

inder number.

72552

a - Piston Ring Compressor (J-8037)

a

5. Remove connecting rod bolt guide.

6. Install bearing caps and evenly torque nuts. Re-

fer to “Specifications”.

7. Check connecting rod side clearance as pre-

viously described.

NOTE:If bearing replacement is required, refer to

“Connecting Rod Bearings.”

8. Install as previously outlined:

a. Oil pump and baffle.

b. Dipstick and oil pan.

c. Cylinder heads.

d. Intake manifold.

e. Distributor.

9. Fill crankcase with oil. Refer to Section 1 - “Main-

tenance.”