Electrical Description of EGM

Status September 2003 (EvoBus-Service / AFT)

Page: 51 of 83

3.4.2.1

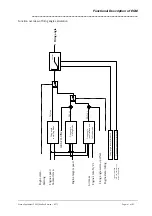

Principle of gas injector actuation

Actuation takes place according to the peak and hold principle with subsequent rapid current switch-off.

The actuation phases and the valve current curve are shown in the following illustration.

Actuation phases and current curve of gas injectors

Push phase

To achieve the pickup current of approx. 2 – 4 A (depending on valve type) as quickly as possible, the

battery voltage is connected to the valve with a high PWM pulse duty factor. The push time to be applied

is selected so that the desired, typical peak current is set. The actuation frequency is 10 kHz. The valve is

already opened before the end of the push phase.

Hold phase

After the push time expires, the system switches over to the holding mode with an actuation frequency of

5 kHz. The suitable selection of the pulse duty factor in this phase reduces the valve current to the

holding current following an e function. The reduced current during the hold phase both decreases the

losses in the valve and output stage, and also reduces the duration of the closing process in the switch-

off phase.

Switch-off phase

After the end of the desired gas injection period, the valve switch-off follows so that the magnetic energy

in the valve discharges against a 37 V switch-off pulse. The switch-off energy is dissipated by the

actuating transistor.

Pick-up

Holding current

Actuation phases of gas injectors

PWM 10kHz

Push

-Phase

PWM 5kHz

Hold-Phase

Switch-Off Phase

U(t)

I(t)

t

t

0V

24V

2 - 4 A

0A

(injector-dependent)

(injector-dependent)