26

SPIRAL MIXER - IM SERIES Operating manual Edition 04-09

CHAPTER 1

GENERAL INFORMATION

1.1 Warranty

Guaranteed for 2 years from date of purchase. The date must be stamped on the guarantee on

the date of purchase. Parts of the machine found to be a production defect exept electrical

components or parts worn out, will be changed and serviced free by us in our firm but only ex our

factory within this period. Delivery expences and costs of labour are excluded from the warranty.

The warranty will not be valid when the damage is due to: transportation, mistaken or insufficient

maintenance, unskilled operators, damaging, repairs made by unauthorized personnel, non-

observance of the instructions of the manual.

All reimbursements from the manufacturer are excluded for direct or indirect damages caused in

the time the machine is inactive for the following reasons: breakdown, waiting to be repaired, or

anyway the nonpresence of the machine.

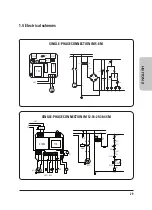

1.2 Characteristics of the machine

The mixers in the models with fixed top and bowl or with raising top and removable bowl were

made with the intention for food usage only, to mix doughs made by cereal flours, for the prevalent

use in: pizza-restaurant, bread and bakery shops.

Every mixer (PICT. 1) is composed of:

·

A steel structure protected by a heat resistant varnish.

·

The bowl, the spiral, the central doughbreaker and the protection grate are all in stainless steel.

·

Chain drive with oilbath gearmotor.

·

The moving parts are on ball bearing.

·

Type feet (from models IM 5 and IM 8), set of wheels (for models from IM 12 to IM 44), type feet

in stainless steel and wheels in nylon (for IM 60)

·

Operation with single-phase or threephase motor, one speed; on request: threephase motor with

two speeds and timer (apart from models IM 5 and IM 8).

·

Electric circuit fed by a cable to the network to which are connected at low tension (24V) the

control devices to start, to stop, and of the safety devices. Among these l'internal blocking of the

moving parts activated by the movement of the mobile protection of the pan.

ENGLISH

Содержание IM 12AD

Страница 1: ...SPIRAL MIXER MODEL IM OPERATING MANUAL ...

Страница 2: ......

Страница 23: ...Note Notes Nòtes Note ...

Страница 24: ......

Страница 25: ......