5

1-WARNINGS AND WARRANTY CONDITIONS

Technical Dept. - All rights reserved - Reproduction prohibited

•

Disconnect the product from the 230V power supply before performing any

maintenance operations.

•

IF ANY SMOKE LEAKAGE IS SEEN WITHIN THE ROOM OR THE APPLIANCE

SUFFERS FROM AN EXPLOSIVE IGNITION PLEASE TURN OFF THE

APPLIANCE, VENTILATE THE ROOM AND CONTACT THE INSTALLER/

SERVICE TECHNICIAN IMMEDIATELY.

INFORMATION

•

If there are any issues, contact the retailer or a qualified technician authorised by MCZ. In the event of a repair, request the use of

original spare parts.

•

Only use types of fuel recommended by MCZ (for Italy, pellets with a 6 mm diameter and pellets with a 6-8 mm diameter for other

European countries), which must only be loaded with an automatic feed system.

•

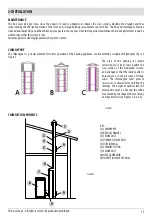

Periodically check and clean the smoke outlet duct (connection to the flue).

•

Accumulated unburnt pellets in the burner after a series of failed ignitions must be removed before lighting it again.

•

The pellet stove is not a cooking appliance.

•

Always keep the cover of the fuel tank closed.

•

Keep this instruction manual, which will be an integral part of the stove for the whole of its service life. If the product is sold or

transferred to another user, ensure the manual is also handed over.

•

If lost, contact MCZ or the authorised dealer to request a copy.

INTENDED USE

The product only works with wood pellets and must be installed indoors.

PRODUCT PERFORMANCE CHECKS.

All our products undergo ITT TESTS carried out by a notified third party laboratory (system 3) and in accordance with Regulation (EU)

number 305/2011 “Construction products”, according to standard EN 14785:2006 for household appliances and “Machinery Directive” EN

303-5 for boilers.

In the case of tests for any market surveillance or inspections by third parties, please consider the following warnings:

•

To reach the declared performance levels, the product must perform an operating cycle of at least 15-20 hours beforehand.

•

Set the average draught of the combustion fumes as specified in the “technical product features” table

•

The type of pellets used must comply with the current EN ISO 17225-2 class A1 regulation. Fir pellets are usually used for certification.

•

The amount of thermal energy can vary according to the length and calorific value of the fuel. This may require some adjustments

(accessed from the user menu) to comply with the hourly consumption specified in the “technical product features” table. Using class

A1 pellets guarantees a calorific value that is likely to be close to that used in the product certification; the size of the pellet grains can

significantly affect hourly fuel loading and consequently performance; it is therefore suggested to use pellets with a 6 mm diameter

and an average length of around 24 mm (avoid pellets that are too long or excessively crushed).

•

With wood-burning appliances, the fuel must comply with the current EN ISO 17225-5 class A1 regulation. Check the correct moisture

of the fuel, as it must be within the range of 12 - 20% (it is best if the moisture is close to 12%, as is normally used in certification). As

the fuel moisture increases, different combustion air settings are required, which are implemented from the combustion air register,

thereby modifying the mixture of primary and secondary air

•

It is important to check the operation of devices that can affect performance (for example air fans or electric safety devices) in case

of damage due to handling.

•

Nominal performance has been obtained by setting the maximum flame power and room ventilation in

manual

mode.

Performance at reduced power was achieved at minimum flame and ventilation power (P1 and V1) in manual mode.

The other conditions (COMFORT SETTING) correspond to intermediate ventilation and power.