5

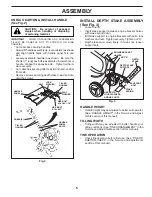

UNPACK CARTON & INSTALL HANDLE

(See Fig. 2)

CAUTION: Be careful of exposed

sta ples when handling or disposing

of cartoning material.

IMPORTANT

:

WHEN UNPACKING AND AS SEM BLING

TILLER, BE CAREFUL NOT TO STRETCH OR KINK

CABLE(S).

• Cut cable ties securing handles.

•

Slowly lift handle as sem bly up, route cable(s) as shown

and align han dle holes with handle panel hole and

slot.

• Loosely assemble hardware as shown. Be sure the

shorter (1" long) hex bolt is assembled in lower hole of

handle. Repeat for opposite side. Tight en all hard-

ware se cure ly.

• Cut cable ties securing tiller to skid and remove tiller

from skid.

• Remove screws securing depth stake to skid and dis-

card the screws.

dep

th_s

tak

e_4

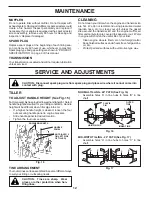

DEPTH

STAKE

SUPPORT

BOLT

HEX BOLTS,

LOCK WASH ERS,

AND HEX NUTS

DEPTH STAKE

SUPPORT

NUT “A”

ENGINE BRACK ET

HALVES

Fig. 3

STAKE

SPRING

TILLER

HANDLES

020

5

1

CABLE(S)

Fig. 2

&4

(ANDLEª0ANEL?

HANDLE

PANEL

BOLTS

FLAT

WASHER

HEX BOLT

5/16-18X1"

TILLER

HANDLE

HAN DLE

PANEL

NUT

LOCK

WASH ER

HEX BOLT

5/16-18X1-1/4"

ASSEMBLY

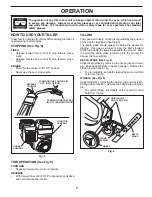

HANDLE HEIGHT

•

Handle height may be adjusted to better suit operator.

(See “HANDLE HEIGHT” in the Service and Ad just -

ments section of this manual).

TILLING WIDTH

• Tilling width may be adjusted to better handle your

tilling con di tions (See “TINE ARRANGEMENT” in the

Service and Adjustments section of this manual).

TINE OPERATION

•

Check tine operation before first use. (See “TINE OP-

ERATION CHECK” in the Service and Adjustments

section of this manual).

INSTALL DEPTH STAKE AS SEM BLY

(See Fig. 3)

• Loosen nut “A”.

• Insert stake support between engine brack et halves

with stake spring down.

• Bolt stake support to engine brackets with bolts, lock

washers and nuts. Tight en se curely. Tighten nut “A”.

• Depth stake must move freely. If it does not, loosen

support bolt.

Содержание 532 43 36-95

Страница 1: ...532 43 36 95 MHDF800 Operator s Manual...

Страница 17: ...17 SERVICE NOTES...