12

TILLER

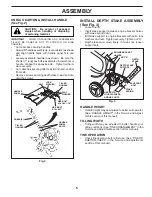

TO ADJUST HANDLE HEIGHT (See Fig. 15)

Factory assembly has provided lowest handle height. Se lect

handle height best suited for your tilling conditions. Handle

height will be different when tiller digs into soil.

• If a higher handle height is desired, loosen the four

nuts securing handle panel to engine brackets.

• Slide handle panel to desired location.

• Tighten the four nuts securely.

HANDLE

PANEL

ENGINE BRACKETS

NUTS (ALSO 2

ON LEFT SIDE

OF TILLER)

Fig. 15

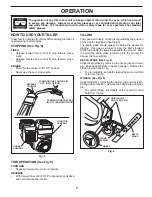

SERVICE AND ADJUSTMENTS

CAUTION: Disconnect spark plug wire from spark plug and place wire where it cannot come into

contact with plug.

Fig. 16

Fig. 17

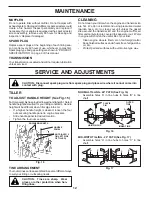

MAINTENANCE

MUFFLER

Do not operate tiller without muffler. Do not tamper with

exhaust system. Damaged mufflers or spark arresters could

create a fire hazard. Inspect pe ri odi cally and re place if

nec es sary. If your engine is equipped with a spark arrester

screen assembly, re move every 50 hours for cleaning and

inspection. Re place if dam aged.

SPARK PLUG

Replace spark plugs at the beginning of each tilling sea-

son or after every 50 hours of use, whichever comes first.

Spark plug type and gap setting are shown in “PROD UCT

SPEC I FI CA TIONS” on page 3 of this manual.

TRANSMISSION

Your transmission is sealed and will not require lubrication

unless serviced.

CLEANING

Do not clean your tiller when the engine and transmission

are hot. We do not rec om mend using pressurized water

(gar den hose, etc.) to clean your unit un less the gasket

area around the trans mis sion and the engine muf fler, air

fil ter and car bu re tor are cov ered to keep wa ter out. Wa ter

in en gine will short en the useful life of your tiller.

• Clean engine, wheels, finish, etc. of all foreign matter.

•

Keep finished surfaces and wheels free of all gas o line,

oil, etc.

• Protect painted surfaces with au to mo tive type wax.

TINE ARRANGEMENT

Your outer tines can be assembled in several different ways

to suit your tilling or cultivating needs.

CAUTION: Tines are sharp. Wear

gloves or other protection when han-

dling tines.

tine_4

OUTER

TINE

INNER TINE

HAIRPIN CLIP

A

B

A

B

CLEVIS

PIN

MID-WIDTH TILLING - 24" PATH (See Fig. 17)

• Assemble holes “A” in tine hubs to holes “C” in tine

shaft.

tine_5

A

C

A

C

NORMAL TILLING - 26" PATH (See Fig. 16)

• Assemble holes “A” in tine hubs to holes “B” in tine

shaft.

Содержание 532 43 36-95

Страница 1: ...532 43 36 95 MHDF800 Operator s Manual...

Страница 17: ...17 SERVICE NOTES...