6

9

1.-

2.-

3.-

4.-

5.-

6.-

7.-

8.-

9.-

10.-

Follow the Pressure Relief Procedure.

If the sprayer has been used before, remove the filter bowl and screen.

Clean the screen separately and install the bowl without the screen to

flush it.

Close the pressure drain valve

For 2 liters of compatible solvent into a grounded metal pail. Put the

suction tube in the pail.

Remove the spray tip from the gun

Lower the pressure setting by turning the pressure adjusting knob all the

way counterclockwise.

Hold a metal part of the gun against a metal container. Squeeze the trigger

and hold it open, turn the ON/OFF switch to ON, and slowly increase

the pressure setting until the sprayer starts. Keep the gun triggered until

all air is forced out of the system and the solvent flows freely from the

gun. Release the trigger and engage the gun safety latch.

Remove the suction tube from the pail. Disengage the gun safety latch

and trigger the gun to force solvent from the hose. Do not let the pump

run dry for more than 15 seconds to avoid damaging the pump packings.

Then follow the Pressure Relief Procedure.

Leave the pressure drain valve open until you are ready to use the sprayer

again. If the screen was removed, unscrew the filter bowl and reinstal the

clean screen. Reinstall the bowl, hand tight.

If you flushed with mineral spirits and are going to use water-base paint,

flush with clean water.

CLEANING

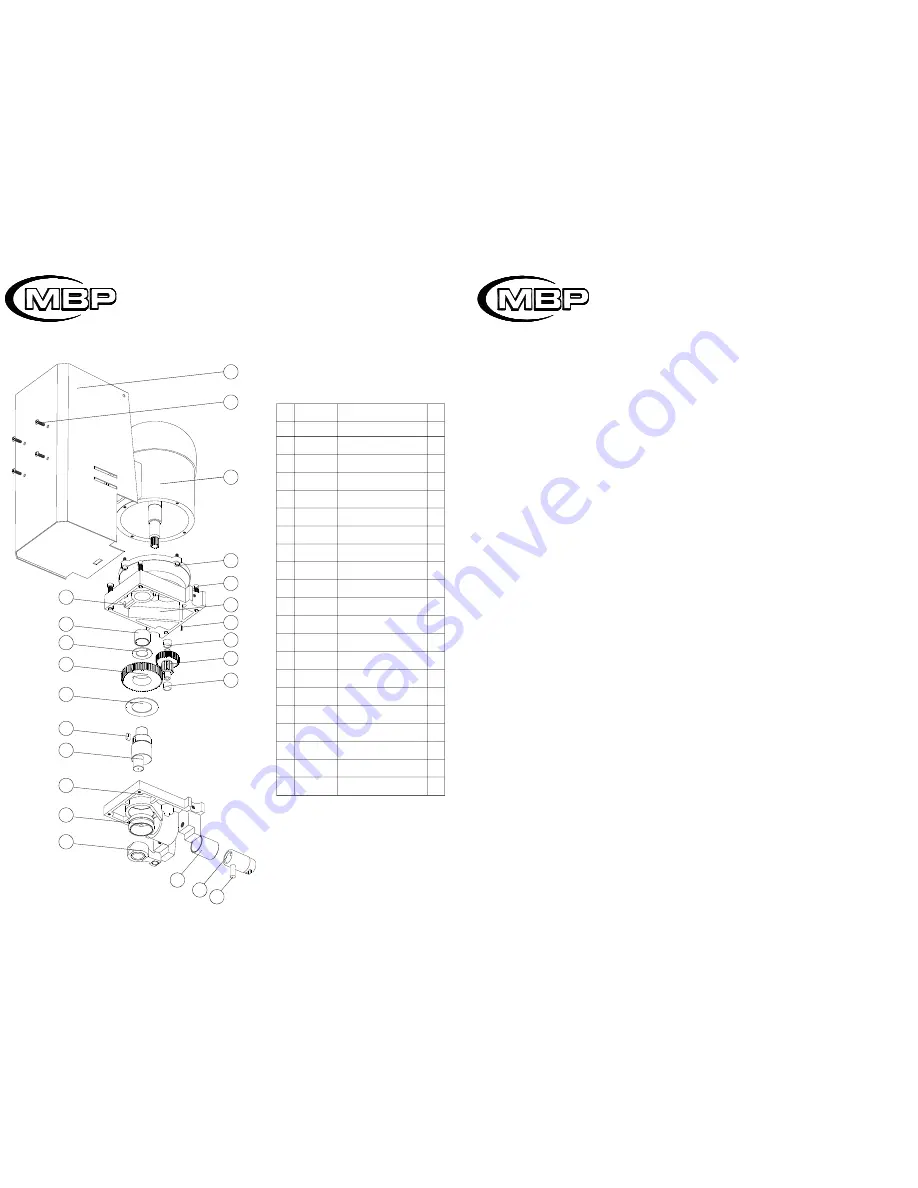

PARTS LIST

REF.

102.110.00

CTB.003

102.111.01

CTB.014

CPA.204

CB1010

A1.920.02

CB1012

CB2007

A1.920.03

CB2008

A1.910.02

CPA.501

102.111.02

CB1009

102.121.00

CB2002

102.120.02

A1.930.03

102.100.01

CTB.204

DESCRIPTION

Motor

Screw

Housing

Screw

Pin

Sleeve

Gear

Bearing

Washer

Gear

Washer

Rod

Cotter pin

Body

Bearing

Rod

Sleeve

Rod

Pin

Cover

Screw

Nº

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Q

1

4

1

4

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

2

3

5

4

8

5

6

10

13

11

12

14

15

16

17

6

7

9

19

18

20

21