Installation and Operational Instructions for

EAS

®

-Compact

®

overload clutch,

Type 49_._ _4._ Sizes 4 and 5

(B.4.14.6.GB)

25/01/2013 GC/NH/GH/SU

Chr. Mayr GmbH + Co. KG

Tel.: +49 8341 804-0

Eichenstraße 1

Fax: +49 8341 804-421

D-87665 Mauerstetten

www.mayr.com

Page

9

of

21

Germany

E-Mail:

Design

The EAS

®

-Compact

®

overload clutch is designed as a

mechanical disengaging overload clutch according to the ball

detent principle.

State of Delivery

The clutch is manufacturer-assembled and set to the torque

stipulated in the order.

Unless the customer requests a particular torque setting, the

clutch will be pre-set to approx. 70 % of the maximum torque.

The adjusting nut (7) is marked with dimension "a" (70% of the

maximum torque, see Figs. 1 and 18).

Please check state of delivery!

Function

The clutch protects the drive line from excessively high,

unpermitted torque impacts which can occur due to unintentional

blockages. After overload has taken place, the transmitting

mechanism is completely disconnected. Only the bearing friction

continues to have an effect.

This means that no re-engagement impacts or metallic sliding

movements occur on the clutch torque transmission geometries

when using this clutch variant.

When in operation, the set torque is transmitted backlash-free

onto the output from the motor shaft via the EAS

®

-Compact

®

overload clutch (pressure flange (2)). If the set limit torque

(overload) is exceeded, the clutch disengages. The input and the

output are separated residual torque-free.

An installed limit switch registers the disengagement movement

and switches off the drive.

After-acting masses can run free

.

CAUTION

The clutch has no load-holding function after

overload occurrence!

Re-engagement

Re-engagement must only take place when the

device is not running or at low differential

speeds (< 10 rpm).

EAS

®

-Compact

®

overload clutch re-engagement is carried out by

applying axial pressure to the thrust washer (3).

For this, the following procedures are possible:

By evenly screwing three screws M8 (not included in

delivery) into the adjusting nut (7).

CAUTION

After re-engagement has taken place, the three

hexagon head screws must be removed

immediately, as they could stop the clutch

functioning (blockage).

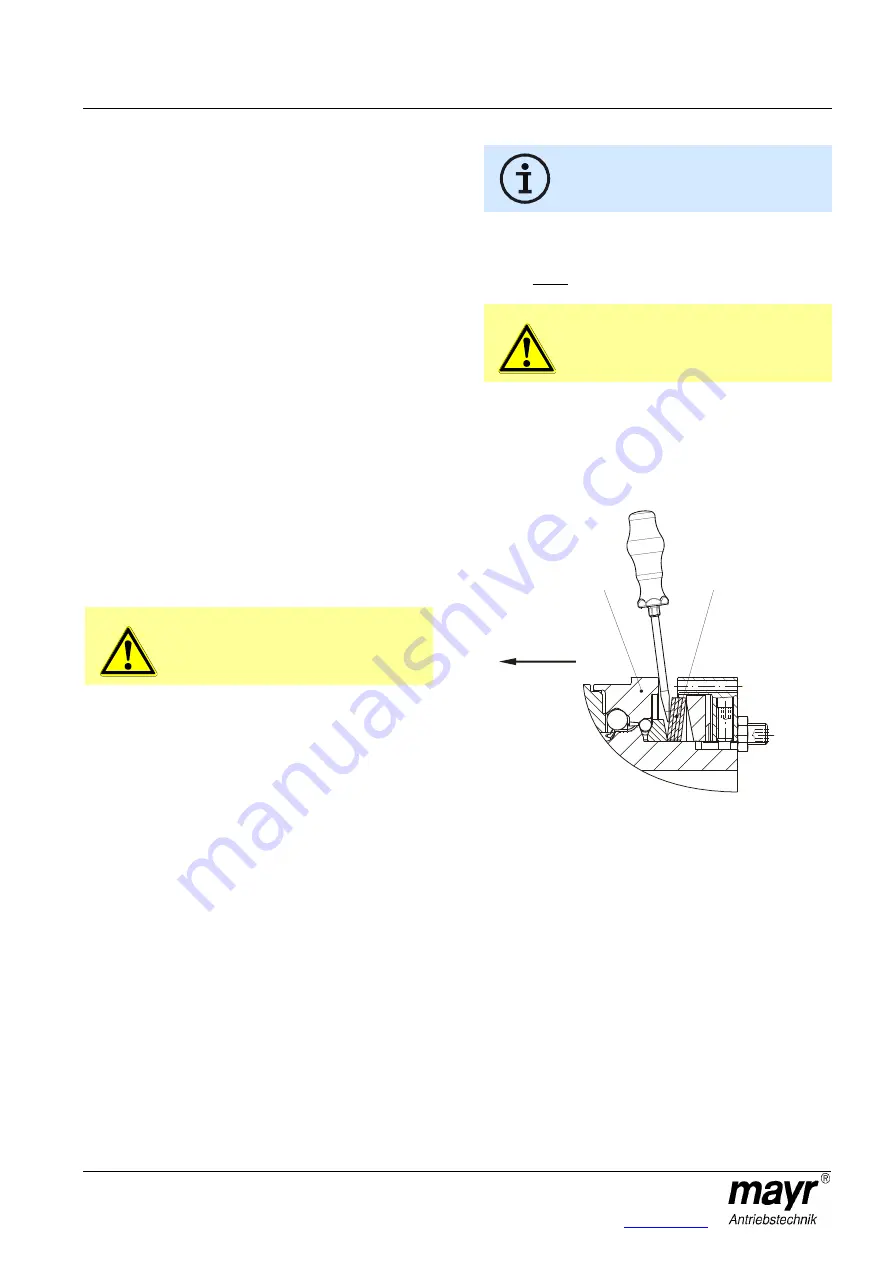

By using two screwdrivers, applied opposite each other

and supported by the cup springs (11), see Fig. 10.

By using an engagement mechanism.

The engagement procedure can also be automated using

pneumatic or hydraulic cylinders.

On all variants, it may be necessary to turn between the clutch

input and output sides slightly.

Fig. 10

General Installation Guidelines

As a standard, the bores in the hubs (1, 23, 26, 32, 36, 39) are

produced with H7 tolerances, the bores in the clamping hubs

(21) with F7 tolerances.

The surface roughness depth in the bores is produced with

Ra = 1,6 µm.

11

3

Re-engagement

direction