7

current values at 400V in Section 1.3 and make sure

to recalculate it for the voltage used on board. Start

current may be limited to about half the above

amount by using a "Star-Delta" starter. However,

start torque is thereby limited to loads of about 25-

30% of the windlass rated capacity.

“Star-Delta” and “soft starters” are not recommended

for starting windlass motors, as the motor torque is

severely limited during start up period. Since these

motors often have to start under load (when

retrieving the ground tackle), they might not be able

to move until they reach the full voltage and torque.

The benefit of starting at lower current would

therefore be lost. Also, the motor brake would

release immediately on start-up, which could cause

short movement of the chain in opposite direction.

The Variable Frequency Drives (VFD) offer accurate

control of current during start up period while

keeping high motor torque. They also offer various

other benefits like:

infinite speed control

running the windlass over its nominal speed

accurate current overload and thermal overload

2.7

POWER CONECTIONS TO AC MOTOR

Remove the motor terminal box cover and take care

not to misplace the sealing gasket and screws.

Select a suitably sized, waterproof cable gland for

the armoured supply cable. The selected gland fitting

must fit the terminal box, be capable of anchoring the

armoured cable, and allow an effective waterproof

entry seal to be made.

Make the line connections to motor terminals as per

motor nameplate or motor card. Fit link plates

correctly, if required. Make also an effective earth

connection.

Separately and similarly, enter the 2 thermistor

cables to the motor terminal box, and connect to the

two auxiliary terminal connectors of the thermistor

circuit (see wiring diagram in Appendix C).

Our AC motors are equipped with a disc brake to

stop back winding when the windlass stops under

load. The brake should be wired as follows:

‘Direct on Line’ start, single speed motor

On single speed motors, the brake rectifier is already

connected to motor terminal block and no additional

wiring is required.

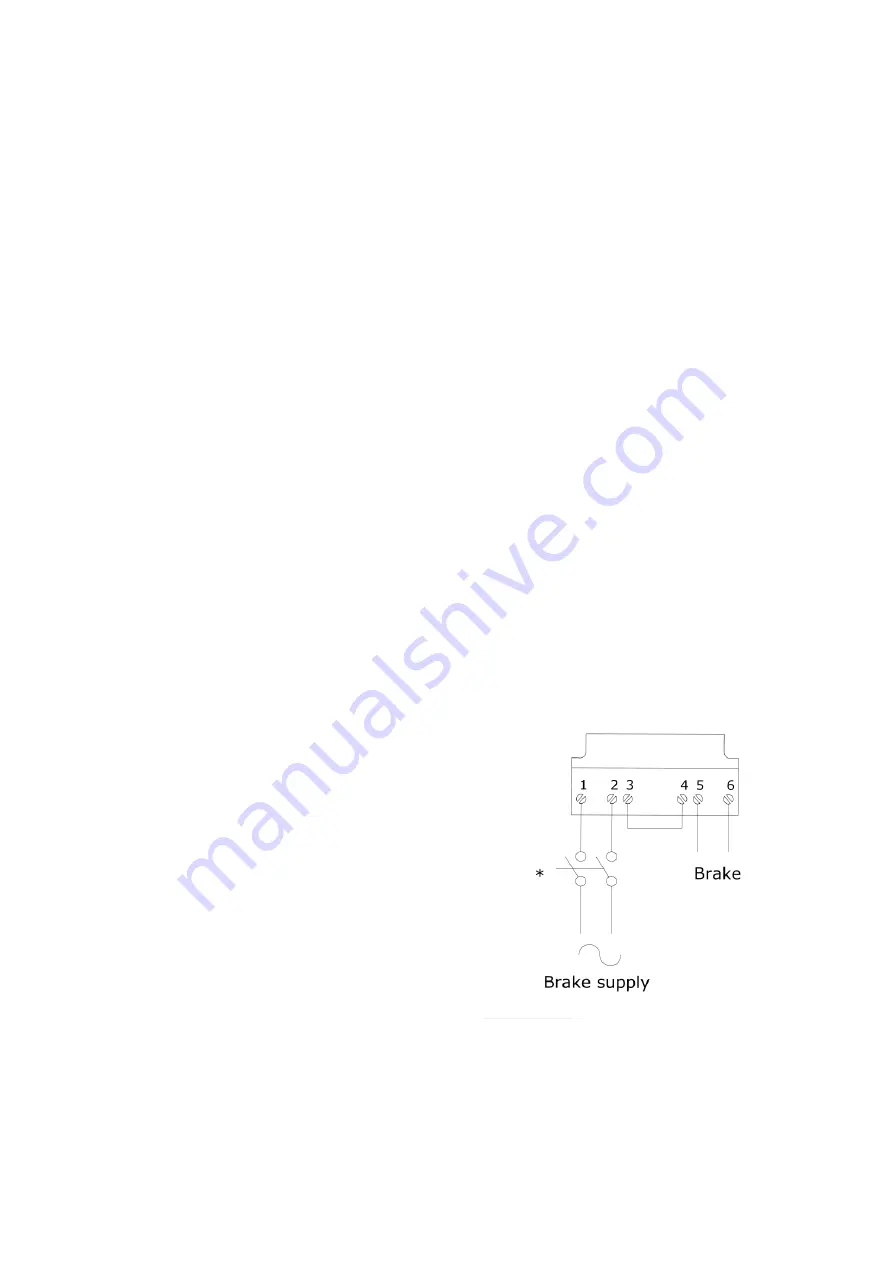

‘Direct on Line’ start, dual speed motor

In case of using a two-speed, pole changing motor, a

separate power supply for the brake is required.

Remove the existing connection from motor

terminals to the brake rectifier and bring in brake

power supply from contactor in the starter unit (see

wiring diagram of DOL starter in Appendix C).

VFD controller

If the VFD, controller is used, the brake also needs a

separate power supply from the VFD unit to ensure

appropriate timing of engaging and disengaging the

*Brake supply contactor should work in parallel

With motor supply contactor. The contacts

Should be suitable to open very inductive

loads

Picture 2.5

Brake Connections

Содержание CAPSTAN 8000 Series

Страница 1: ...CAPSTAN 8000 SERIES...

Страница 15: ...13 APPENDIX A Dimensional Drawings...

Страница 16: ...14...

Страница 17: ...15...

Страница 21: ...19 APPENDIX C Installation Schematics...

Страница 22: ...20...

Страница 23: ...21...

Страница 24: ...22...

Страница 27: ...25...