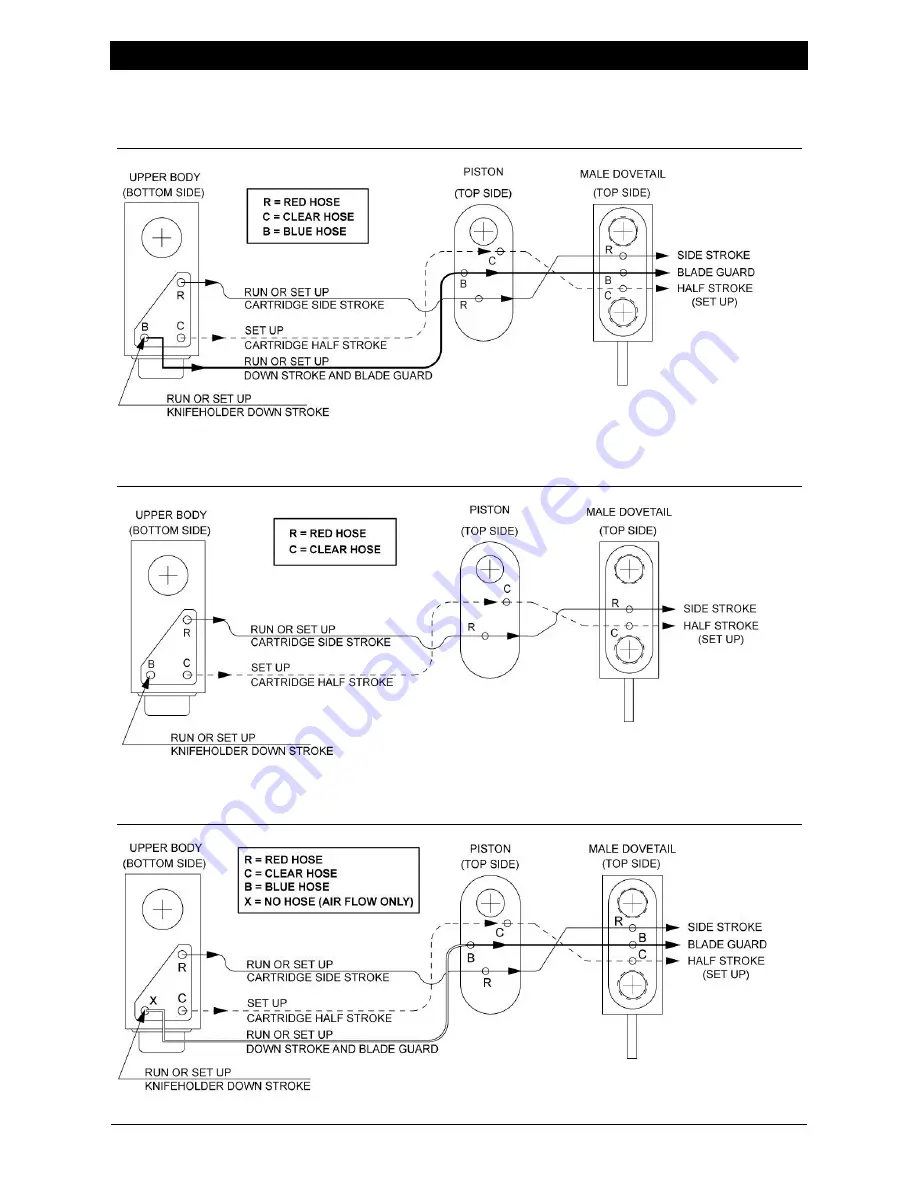

AIR FLOW SCHEMATICS

www.maxcessintl.com

Tidland Performance Series Automatic Knifeholder

MI 557417 1 AD

Page 50

Lift the bellows on Class I knifeholders to see hose layout and determine appropriate schematic.

Class I (before June 2003)

Class I (after June 2003)

Class I (after Sept 2010)