N

‐

i

‐

HP

Inverter

air

/

water

heat

pump

chillers

with

axial

fans

15

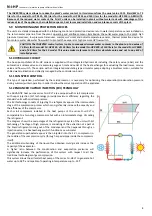

7.5.4

Refrigerant

diagram

of

the

model

N

‐

i

‐

HP

‐

LT

0235

‐

0250

C

COMPRESSOR

ST

COMPRESSOR

INLET

TEMPERATURE

DT

COMPRESSOR

OUTLET

TEMPERATURE

HP

HIGH

PRESSURE

TRANSDUCER

Pr

HIGH

PRESSURE

FLOW

SWITCH

LP

LOW

PRESSURE

TRANSDUCER

LS

LIQUID

SEPARATOR

4WV

CYCLE

REVERSING

VALVE

LR

LIQUID

RECEIVER

EEV

ELECTRONIC

EXPANSION

VALVE

FL

FILTER

M

AXIAL

FAN

SE

OUTDOOR

AIR

TEMPERATURE

P

CIRCULATOR

ON

BOARD

UNIT

IN

WATER

INLET

TEMPERATURE

OUT

WATER

OUTLET

TEMPERATURE

NRV

NO

RETURN

VALVE

INJ

INJECTION

VALVE

V

ON/OFF

VALVE

WITH

SOLENOID

PV

PRESSURE

CHECK

VALVE

INJT

INJECTION

TEMPERATURE

INJP

INJECTION

PRESSURE

TRANSDUCER

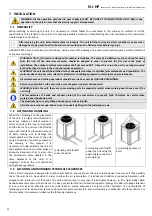

7.6

ELECTRICAL

CONNECTIONS

Check

if

the

power

supply

circuit

meets

the

unit’s

electric

nominal

data

(tension,

phases,

frequency)

reported

on

the

label

sticked

on

the

right

‐

side

panel

of

the

unit.

The

wiring

must

be

done

in

accordance

to

the

wiring

diagram

attached

to

the

unit

and

in

conformity

with

the

national

and

international

norms

in

force

(attempting

to

provide

a

general

magnetothermic

circuit

breaker,

differential

circuit

breakers

for

each

electric

line,

proper

grounding

for

the

plant,

etc.).

Power

cables,

electric

protections

and

line

fuses

have

to

be

sized

according

to

the

specifications

listed

in

the

wiring

diagram

enclosed

with

the

unit

and

in

the

electrical

data

contained

in

the

table

of

technical

characteristics

(see

Paragraph

13).

Because

of

the

presence,

inside

the

machine,

of

EMC

filters

for

compliance

with

EMC

limits

(interference

emission

and

interference

immunity),

earth

fault

currents

up

to

250

mA

of

intensity

can

be

detected.

For

proper

installation,

electrically

connect

the

unit

with

a

dedicated

line;

if

you

use

a

residual

current

circuit

breaker,

choose

a

four

‐

pole

one,

with

a

trigger

threshold

of

300

mA

and

delayed

triggering

(super

‐

resistant,

characteristic

K).

The

machine

must

be

installed

in

TN

‐

S/TT

power

supply

earthing

systems.

The

electrical

installation

must

be

carried

out

in

accordance

with

norms

in

force.

WARNING:

The

supply

voltage’s

fluctuations

can

not

exceed

±5%

of

the

nominal

value.

Should

this

tolerance

not

be

respected,

please

contact

our

technical

department.

WARNING:

The

power

supply

have

to

respect

the

listed

limits:

failing

this,

warranty

will

terminate

immediately.

Before

any

operation

on

the

unit,

be

sure

that

the

power

supply

is

disconnected.

WARNING:

The

water

flow

switch

(B

component

in

the

previous

hydraulic

circuit

and

factory

installed)

have

ALWAYS

to

be

connected

following

the

indications

listed

in

the

wiring

diagram.

Never

bridge

the

water

flow

switch

connections

in

the

terminal

board.

Should

the

water

flow

switch

connections

altered

or

not

properly

made,

the

guarantee

will

be

invalidated.

WARNING:

The

opening

of

the

separating

plate

between

the

1st

and

2nd

level

of

the

electrical

box

is

permitted

only

to

qualified

personnel.

When

lowering

the

separating

plate,

be

careful

not

to

damage

the

wiring

harness

that

connects

the

inverter

boards.

Before

lowering

the

separating

plate,

unplug

the

communication

cables

of

the

inverter

boards

(see

the

wiring

drawings

"Control

Signals

1",

section

24.2,

24.6,

24.11,

24.15;

these

cables

are

marked

in

the

drawings

with

the

words:

I

‐

,

I

+,

GND,

I2

+,

I2

‐

,

GND2

).

WARNING:

The

remote

control

panel

is

connected

to

the

water

chiller

by

means

of

no.4

wires

having

a

1,5

mm

2

section.

The

power

supply

cables

have

to

be

separated

from

the

remote

control

wires.

The

maximum

distance

is

50m.

WARNING:

The

remote

control

panel

can

not

be

installed

in

areas

with

strong

vibrations,

corrosive

gases,

and

excess

of

dirtiness

or

high

humidity

levels.

Leave

free

the

area

near

the

cooling

openings.

Содержание i-HP 0235

Страница 53: ...ADVANTIX SPA Via Mansoldo Gettuglio Loc La Macia Z A I 37040 ARCOLE Verona NOTES...

Страница 54: ...N i HP Inverter air water heat pump chillers with axial fans 53...

Страница 55: ......

Страница 56: ...Serial number...