www.masterweld.co.uk

Copper and alloys

The most important factor is the high rate of heat conductivity of

copper, making preheating of heavy sections necessary to give

proper fusion of weld and base metal.

Types of electrodes

Arc welding electrodes are classified into a number of groups

depending on their applications. There are a great number of

electrodes used for specialised industrial purposes which are not of

particular interest for everyday general work. These include some

low hydrogen types for high tensile steel, cellulose types for welding

large diameter pipes, etc. The range of electrodes dealt with in this

publication will cover the vast majority of applications likely to be

encountered; are all easy to use and all will work on even the most

basic of welding machines.

Metals Being Joined and

Electrode Comments

Mild steel

6013 ideal electrodes for all general-purpose work. Features include

outstanding operator appeal, easy arc starting and low spatter.

Mild steel

7014 all positional electrode for use on mild and galvanised steel

furniture, plates, fences, gates, pipes and tanks etc. Especially

suitable for vertical down welding.

Cast iron

99% nickel suitable for joining all cast irons except white cast iron

Stainless steel

318l-16 high corrosion resistance. Ideal for dairy work, etc.

On stainless steels vertical, lift the torch up from the work piece to

draw out an arc. To prevent melting of the end of the tungsten so this

in a smooth rapid movement

TIG welding guide ranges.

6.8 Basic TIG Welding Guide

TIG welding cable connection

Connect the TIG torch to the - terminal and the work lead to the +

terminal for direct current straight polarity. Direct current straight

polarity is the most widely used polarity for DC TIG welding. It allows

limited wear of the electrode since 70% of the heat is concentrated

at the work piece. Connect the gas hose on the TIG torch to the gas

outlet on the gas regulator. Move the selector switch on the front

panel of the machine to the LIFT-TIG position.

Torch starting in LIFT-TIG mode

To operate in TIG welding mode select JOB 6 on the right control

and the left display will show amperage and the right display will

show TIG. You can adjust the welding amperage with the left control.

Ensure the gas supply is switched on and gas is flowing from the

front of the torch nozzle. Briefly contact the tip of the tungsten

electrode down onto the work piece with the torch at around 70º

from vertical, lift the torch up from the work piece to draw out an arc.

To prevent melting of the end of the tungsten so this in a smooth rapid

movement.

6.9 Additional Functions

6.9.1 Memory function

RAPID panel has 3 memory location available which can be

selected using button 5

PRO panel has up to 100 memory locations available. The number

of memory locations available to the use can be set.

Auto save is enabled by default and after adjusting any of the

parameters the memory display will flash to show it is saved.

Altering the number of memory locations available (PRO panel).

Press and hold the F button for 5 seconds. Select F45 and increase

or decrease the number of memory locations to suit the user.

Switching off Auto Save. Press and hold the F button for 5 seconds.

Select F44 and set the value to zero. With auto save off it is now

required to press and hold the down button (5) until the memory

display goes out which confirms the save. You can switch on

Auto save again by setting the value of F44 to 01.

6.9.2 Supervisor Lock

It is possible to set the machine in lock mode so that the operator

can only use JOBs that have been saved to memory. To activate the

lock function first program the machine as required for the user and

then follow the following steps to activate the lock.

Switch off the machine press the mem down arrow (5) and hold

while switching on the machine until you see LOC on the display

and then rotate the right hand knob so the value is 01 (On). It will

now not be possible to adjust any parameter other than the memory

location and the voltage trim.

To remove the lock switch off the machine press the mem down

arrow (5) and hold while switching on the machine until you see

LOC on the display and then rotate the right hand knob so the value

is 00 (Off).

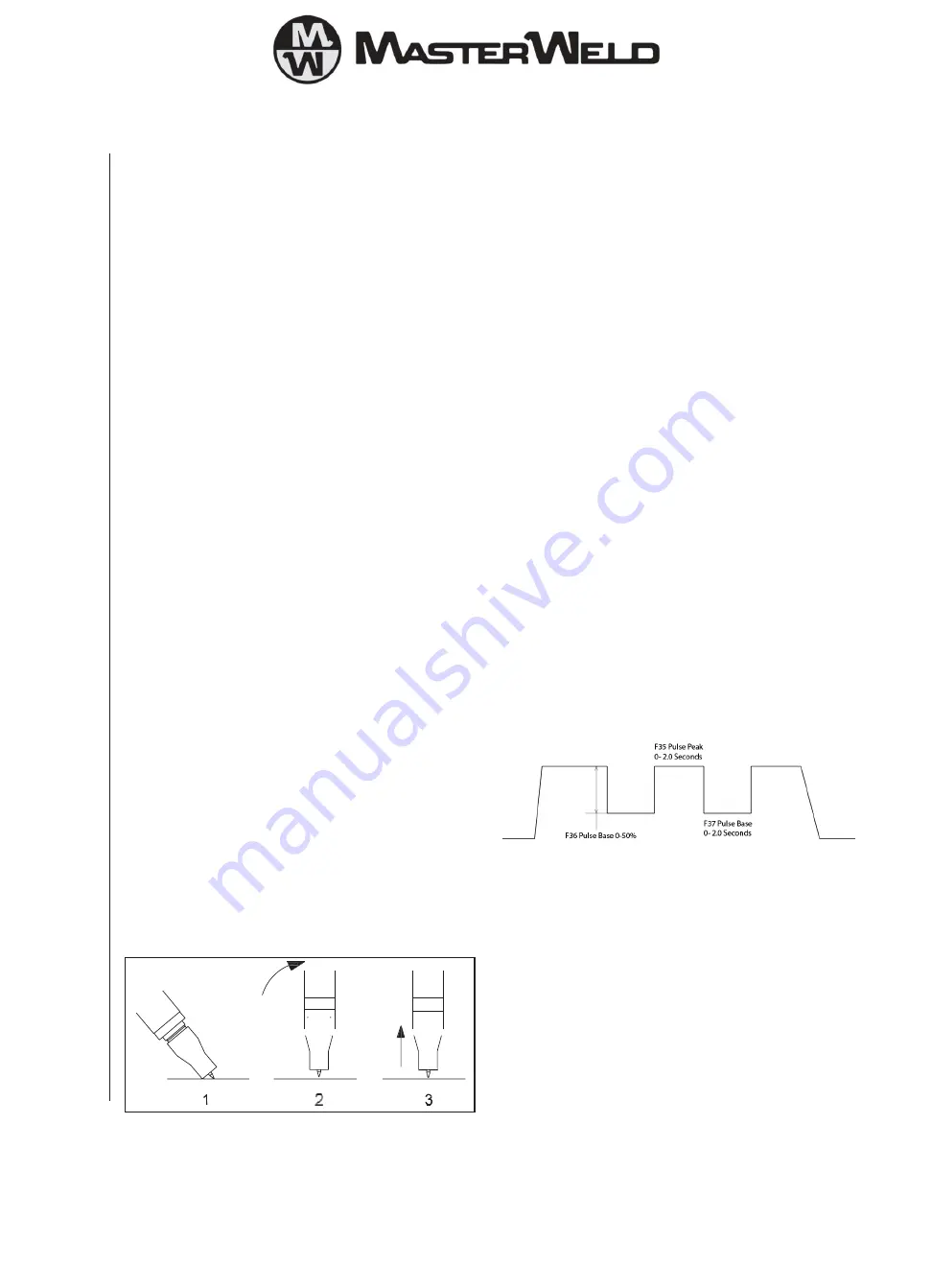

6.9.3 Pulse Balance Adjustment

The standard preset double pulse function should be suitable for all

applications but if you need to change the double pulse parameter

you can do so as detailed below

Using the F functions F35, F36, F37 and F38

F35 is the time spent and the peak (normal) power level and can be

adjusted from 0 to 2.0 Seconds. Increasing this parameter will give

increased heat input and a wider spread of the weld pool.

F36 is the difference between the normal power level and the low

power level. It can be adjusted from 0 to 50% at 50% the low power

level will be 50% less than the normal power level.

F37 is the time spent and the base (low) power level and can be

adjusted from 0 to 2.0 Seconds. Increasing this parameter will give

reduced heat input

F38 is the voltage trim for the base current level and can be adjusted

+/- 0 to 9.9 volts

14