Component removal & reinstallation

17

4. Loosen the tilt adjustment Allen screw (B) on the side of the beam adjustment ring. Adjust the tilt

angle from 0 - 15° by pushing down gently on the side of the lamp module top plate. Retighten

the tilt adjustment screw (B). Replace the lens.

5. Check that the target is illuminated as intended. If not, repeat step 4. When the desired

illumination is obtained, the tilt angle can be read from the guide next to the tilt adjustment screw

and noted for future reference.

6. Replace the front glass with its seal and trim ring, gradually cross-tightening the trim ring screws

to a maximum torque of 1.8 Nm/1.3 ft-lbs (see

“Front glass and lens: removal and refitting”

Condensation and humidity

The Inground 200 is fitted with a self-purging valve that eliminates humidity problems. Any initial

condensation after installation will gradually disappear in normal use.

9. Component removal & reinstallation

Tasks such as beam adjustment, lamp replacement and cable connection require the removal and

reinstallation of certain components. This section contains instructions for these procedures.

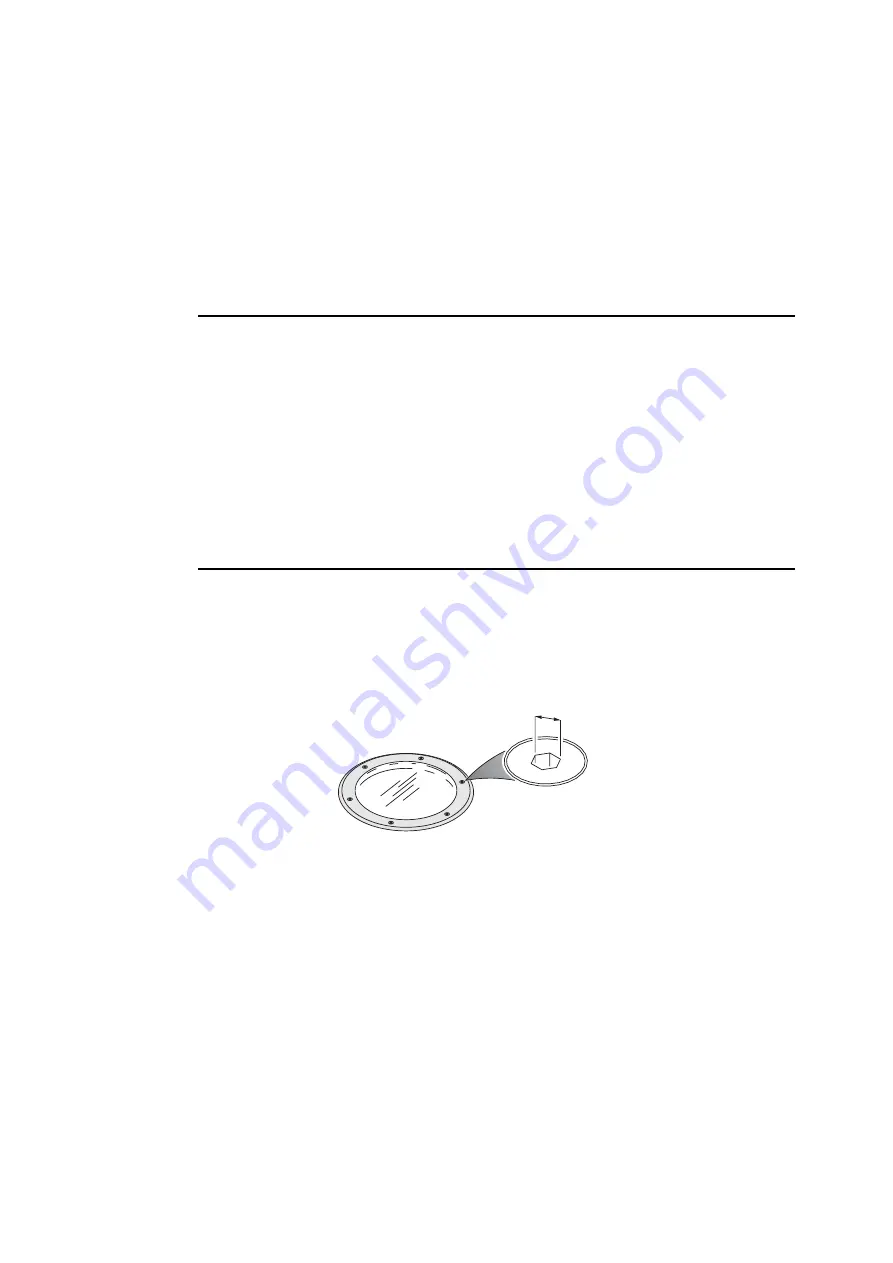

Front glass and lens: removal and refitting

A 4mm Allen key is required for this operation.

1. Isolate the Inground 200 from AC power and allow to cool for at least 15 minutes.

2. Brush sand, dirt, etc. away and clean the Inground 200 and surrounding area to ensure that dirt

does not fall into the fixture.

3. Remove the six countersunk 4mm Allen screws and lift the trim ring off the fixture

4. Taking care to avoid damaging the seal, lift off the front glass and its seal.

5. Lift the lens out of the housing.

Refitting the lens and front glass

Important! Any damaged seals or screws must be replaced with new items. Two spare 4mm

countersunk Allen screws for the trim ring are supplied with the fixture.

The front glass seal, its seating surface in the housing, the front glass and the trim

ring must all be perfectly clean and dry to maintain a waterproof seal.

Warning!

Do not use silicone or any other kind of sealant on the front glass seal, front glass,

housing or trim ring. Doing so will invalidate the product warranty.

4mm