3-2

3-2

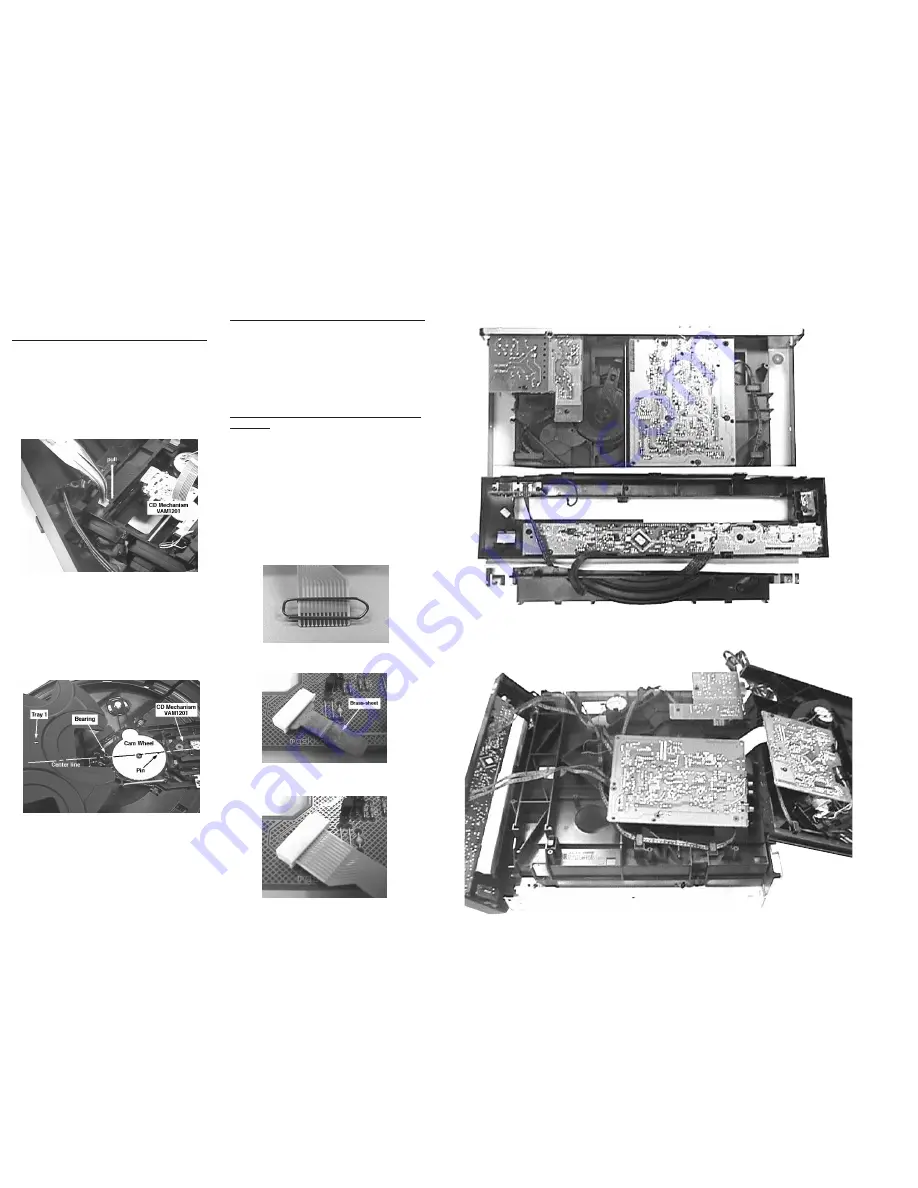

Assembly of the CD mechanism and Rotary disc CDC5

1) Remove the 4 rubber suspension (pos 104-107) from the

Support bracket (pos 114) and attached them on to the

CD mechanism.

2) Place the CD mechanism with the rubber suspension

above the mounting 4 holes.

3) Hold the CD mechanism in position and pull the tips of the

rubber suspension through the holes in the Support

bracket.

4) After assembly of the CD Mechanism, the Cam wheel (pos

116) and the Rotary disc (pos 100) must be re-aligned.

This is done by positioning the Bearing (pos 101), pin on

the Cam wheel and CD Mechanism in a straight line as

indicated.

5) Assemble the Rotary disc onto the Bearing with the "1"

printing mark facing the CD Mechanism.

Warning

Charged capacitors on the Servo board may damage the

CD drive electronics when connecting a new CD mecha-

nism. That's why, besides the safety measures like

* Switch off power supply

* ESD protection

Additional actions must be taken by the repair techni-

cian.

The following steps have to be done when replacing the CD

Mechanism:

1) Disconnect the old CD mechanism flexfoil from printed

board.

2) Connect paperclip to CD mechanism flexfoil to short-

circuit flexfoil (fig.1).

3) Short-circuit printed board with brass-sheet (4822 321

11197) plugged into the flexfoil connector (fig. 2).

4) Remove the old CD mechanism.

5) Assemble the new CD mechanism into position.

5) Remove short-circuit from printed board connector.

6) Remove short-circuit from flexfoil of new CD mechanism.

7) Connect new flexfoil to print connector (fig. 3).

Figure 3

Figure 2

Figure 1

SERVICE POSITION 2

SERVICE POSITION 1

PCS 101 016

Содержание CC-4000 OSE

Страница 11: ...4 1 4 1 SET BLOCK DIAGRAM µP FTD CC4000 CC4000F only ...

Страница 28: ...10 1 10 1 EXPLODED VIEW FRONT PART 3139 119 31850 sh110 1 CC4000 CC4000F only ...

Страница 29: ...10 2 10 2 EXPLODED VIEW REAR PART 3139 119 31850 sh110 2 ...

Страница 30: ...10 3 10 3 EXPLODED VIEW CDC5 LOADER PCS 101 038 ...