1. Safety Warnings

WARNING Hazardous location environment

. This unit is suitable

for use in Class I, Division 2 groups A, B, C and D or Non-Hazardous

locations only.

WARNING

All input and output (I/O) wiring must be in accordance

with Class I, Division 2 wiring methods and in accordance with the

authority having jurisdiction.

WARNING Explosion hazard.

Do not disconnect equipment unless

power has been switched off or the area is known to be non-hazardous.

WARNING Explosion hazard.

Do not connect more than one main

power supply to any one fuse or circuit breaker.

WARNING Explosion hazard.

Substitution of components may

impair suitability for Class I, Division 2.

1.1. Hazardous Locations

Install the MicroOIT terminal using publication NFPA 70E, Electrical Safety

Requirements for Employee Workplaces as a guide. Be certain to follow all

directions for installing and connecting DC power to the MicroOIT.

When used in a hazardous environment, the ultimate enclosure must be in

accordance with Class I, Division 2 wiring methods as described in the National

Electrical Code (ANSI/NFPA 70).

All peripheral equipment must be suitable for the location in which it is used.

Use only a Class 2 power source as described in the National Electrical Code

(ANSI/NFPA 70).

WARNING

Use only with Class 2 power source limited to 30 VDC

open circuit and 8A short circuit.

1010-0105, REV 03

6

OIT3160B/4160B

4. OIT Configuration Wiring

The OIT3160 and OIT4160 must be configured for a particular protocol before use.

The OITware-200 or STEPware-100 software (used on a computer with Windows

3.1 or later) is used for OIT configuration. For detailed instructions on installing

and using the software, please refer to the software documentation.

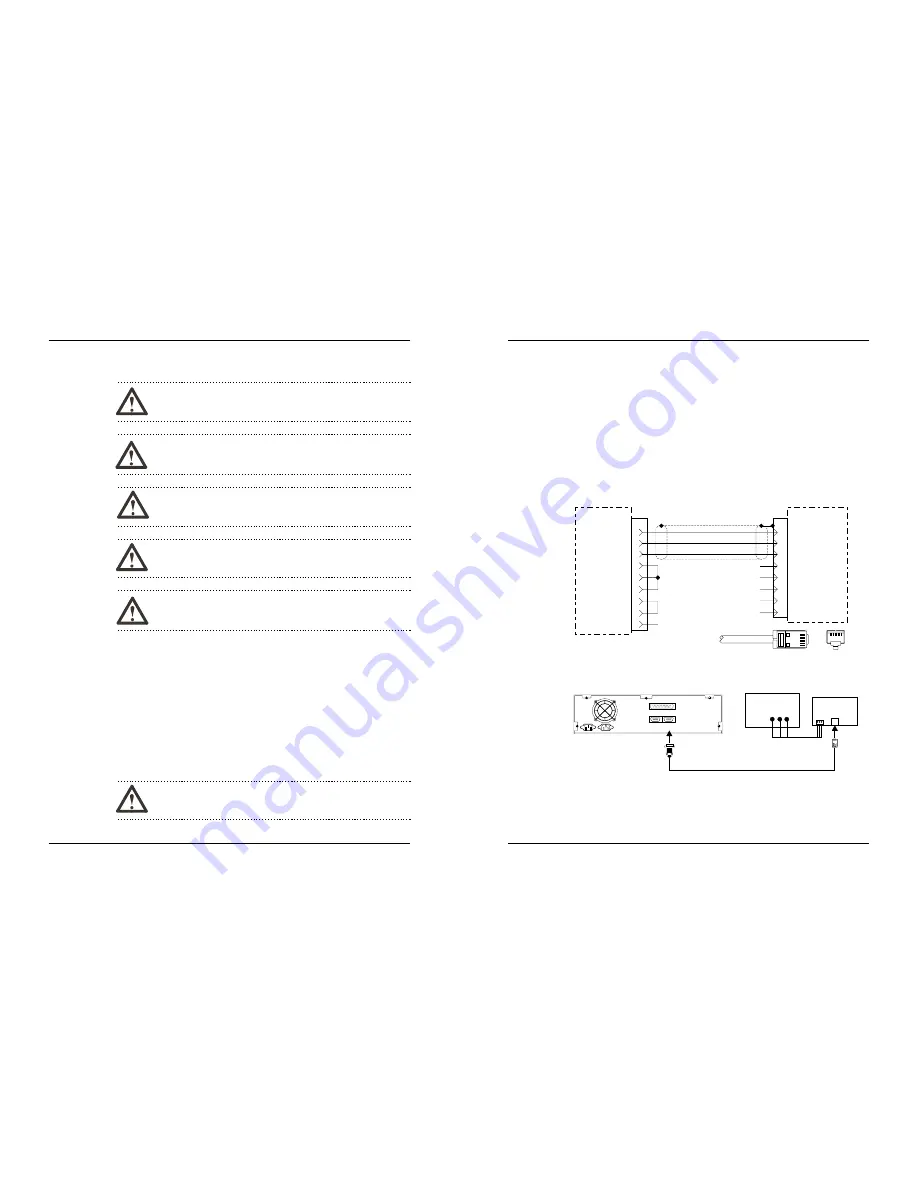

4.1. Connect OIT to PC for Configuration

To configure the OIT using Maple Systems’ configuration software, remove the

PLC/host cable from the serial port on the OIT and connect the OIT to the computer

using an RS-232 serial communications cable (P/N 7431-0096, purchased

separately from Maple Systems). The configuration cable should be connected to

the proper COM port on your computer, then attached to the serial port on the OIT.

See Figure 7 below for serial port pin assignments.

INSTALLATION MANUAL

15

1010-0105, REV 03

CTS

DSR

RTS

DCD

DTR

8

7

6

4

1

RXD

TXD

6

5

RJ-45

OIT

PC

4 Return

Ground 5

TXD 3

RXD 2

9S

1 TXD+

2 TXD-

3 CTS

7 RXD-

8 RXD+

N/C

N/C

N/C

N/C

N/C

9

N/C

Top

8

1

8

1

Pin Configuration

RJ-45 Plug

Printer

Com2

Back

of

OIT

7431-0096

Com1

OIT

PC

OIT Power Supply

Power

Maple Systems

OIT to PC cable

(If mouse is using

Com 1, use Com2)

Figure 7 OIT3160/4160 to PC RS-232 Communication