1.

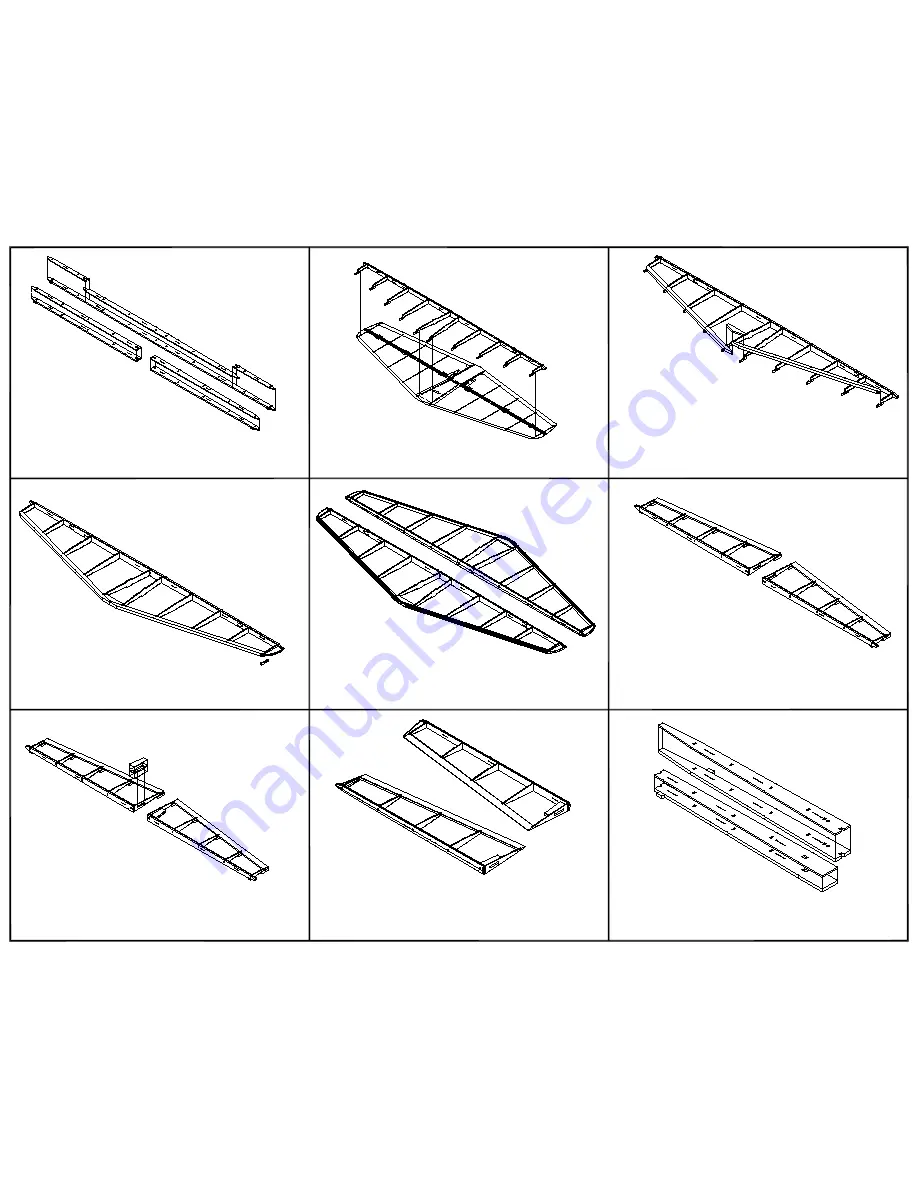

Begin with the stab and elevators. Assembly begins by

laminating the spars. They are made up from a lamination of 1/8"

balsa and a lamination of 1/16" plywood.

Dry fit the stab ribs to the stab spar. Make sure the tabs on the

spar tips face down.The plywood laminations faces the r bs.

Place the assembly over the plan.

With the stab assembly lined up over the plan, dry fit the leading

edges to the r bs. They will lie flat on the rib tabs. The nose of

each rib fits in the leading edge notches. When everything is

properly aligned apply glue to all joints. Also glue the 1/8" balsa

joined to the center joint of the leading edge pieces.

2.

3.

4.

5.

6.

7.

8.

9.

Remove the stab assembly from the plan. The r b and spar tabs

can be removed at this time. The 1/16" balsa center section

sheeting will be installed during the final assembly steps.

Glue the stab tips to the assembly. The leading edge, tips, and the

back side of the spar can now be sanded to shape. Refer to the

plan cross section drawings for the shape of the spar back face.

The elevators are assembled using the same procedure as the

stab. Dry fit the r bs to the spars and then place on the plan. The

plywood side of the spars face the ribs. Add the trailing edge

pieces so the rear of each rib engages the notches. When

everything is lined up glue all of the joints.

Plywood boxes made from laminations of 1/32" plywood are used

to transfer the elevator control horn inputs to the elevator halves.

Glue the parts for each horn box and then install them in the

elevator halves. The tabs fit in elevator rib E1.

Remove the r b and spar tabs. Glue the elevator tips to the

assemblies. Sand the forward edge of each elevator half to the

profile shown on the plan cross section drawing. Sand the trailing

edge to a taper following the the rib top and bottom profile. Also

sand the elevator tips.

The fin and rudder assembly is very similar to the stab and

elevator halves. Begin by making up the fin and rudder spars.

They are laminated from 1/8" balsa and 1/16" plywood.

Содержание deHavilland DHC-1 Chipmunk

Страница 1: ...deHavilland DHC 1 Chipmunk Assembly Guide Manzano Laser Works ...

Страница 3: ......

Страница 4: ......

Страница 5: ......

Страница 6: ......

Страница 7: ......

Страница 8: ......

Страница 9: ......

Страница 10: ......

Страница 11: ...TAIL SURFACES ASSEMBLY ...

Страница 14: ...WING ASSEMBLY ...

Страница 19: ...FUSELAGE ASSEMBLY ...

Страница 24: ...FINAL STRUCTURAL ASSEMBLY ...