A

05.03

7

Introduction

CHAPTER

PAGE

ISSUE

CHASSIS

ENGLISH

SECTION 1

A

- CHASSIS

F. 1

F. 3

F. 2

GENERAL WORK PROCEDURES

• The

advice

,

recommendations

and

warnings

given hereafter are aimed at ensuring maximum work safety as

well as at considerably reducing the risk of accidents, personal injury, equipment damage and idle times. They

should therefore be strictly adhered to.

ADVICE:

• Only use quality tools and equipment.

• Only use equipment conforming to EU Directives for lifting the vehicle.

• During operations, always keep tools and equipment at hand, possibly laying them out according to the sequence in which

they are to be used. Absolutely avoid putting them on the vehicle itself, out-of-sight or in poorly accessible places.

• Always keep the work area clean and tidy.

• When tightening screws or nuts, start with the

larger diameter

or inner fasteners, and tighten them in progressive

“pulls”

in accordance to a

“criss-cross”

pattern.

• Preferably use open-end box wrenches by

“pulling”

and not “pushing”.

• Adjustable wrenches (F. 1) should only be used in case of emergency, i.e. when a properly sized wrench is not available.

they should preferably not be used as the movable jaw tends to open thus risking damaging or not properly tightening the

bolt to the correct torque.In any case, when using an adjustable wrench, take care to proceed as shown in Figure 1.

• Except for occasional customers, always make out and deliver to the customer a

work sheet

specifying the operations

performed, with notes as to any future checks eventually required.

RECOMMENDATIONS:

•

Before carrying out

any operation on the vehicle, wait for

all parts to cool down

.

• For operations requiring two mechanics, make sure that the various steps to be performed by each of them are

clearly defined and coordinated beforehand.

• Make sure that each component has been properly fitted before proceeding with the next one.

• Lubricate all parts (where applicable) before reinstalling them.

• Gaskets, O-rings, circlips and split pins

must be replaced

at every refitting.

• The torque settings specified in the manuals refer to the

“final torque”

, which must be attained progressively by

steps.

• Loosen and tighten aluminium alloy parts (covers) only after

the engine has fully cooled down

.

• Only use screwdrivers with sizes suitable to the screws to be loosened or tightened.

•

Work in a comfortable position and ensure that the vehicle is stable.

• Never use a screwdriver as a lever or chisel.

• Never use pincers to loosen or tighten screws or nuts because, in addition to not providing a sufficient clamping

force, they may also damage the screw head or nut hexagon.

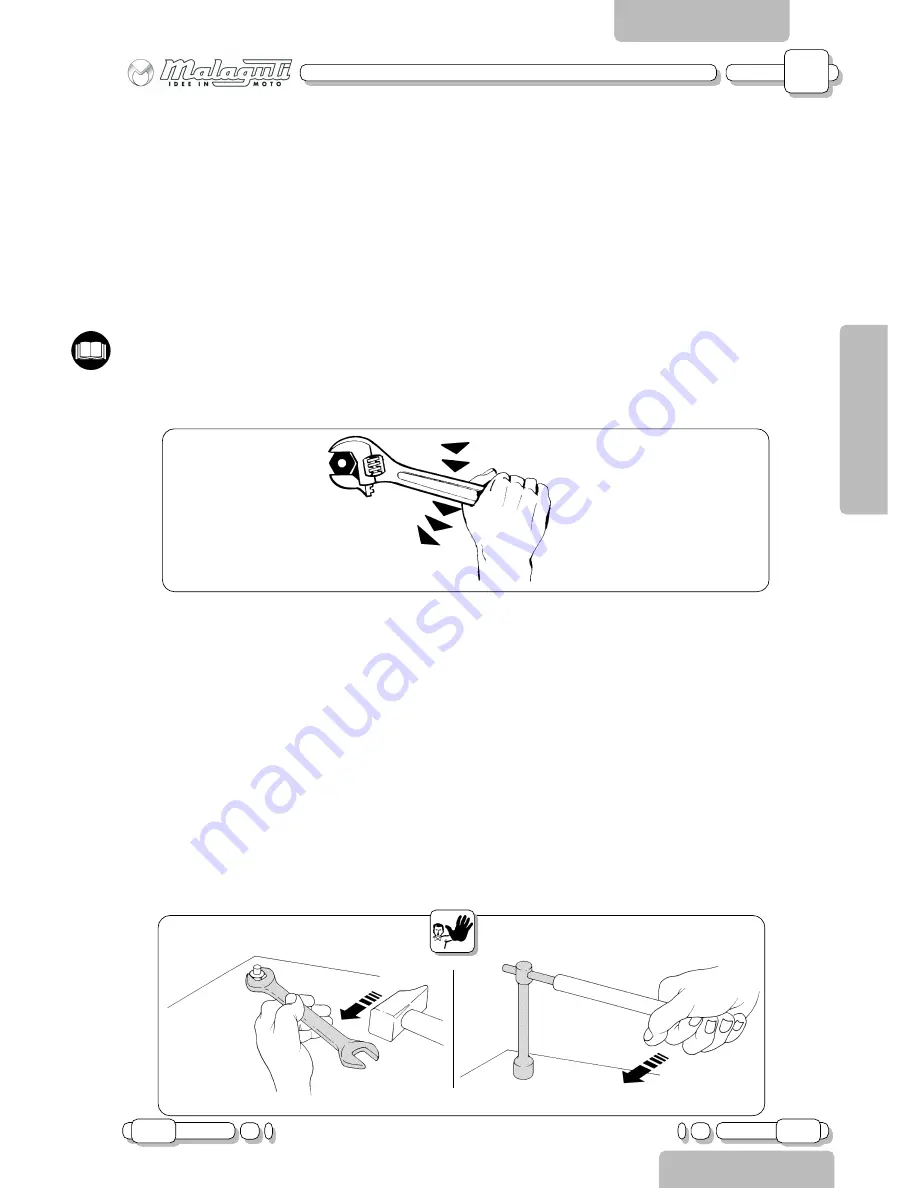

•

Never tap the wrench with a hammer

or other similar tools to loosen or tighten screws and nuts (F. 2).

•

Never attempt to increase the lever arm

by fitting a tube into the wrench (F. 3).

Содержание XTM 50

Страница 1: ...XTM XSM A WORKSHOP MANUALS CHASSIS...

Страница 2: ......

Страница 42: ...A 42 05 03 CHAPTER PAGE ISSUE CHASSIS ENGLISH SECTION 2 Disassembly XTM XSM SECTION 3 A CHASSIS...