P 2/ 10

[1] NECESSARY REPAIRING TOOLS

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Code No.

Description

Use for

1R004

Retaining ring pliers ST-2

removing Retaining ring WR12 from Spindle

1R005

Retaining ring pliers RT-2N

removing Retaining ring R-32 from Gear housing

1R026

Bearing setting pipe 16-8.2

removing Spindle from Helical gear 37

1R028

Bearing setting pipe 20-12.2

assembling Helical gear 37 and Cam

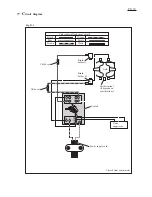

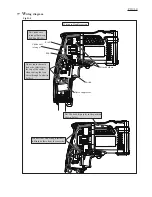

[2] LUBRICATION

Apply

Makita grease N. No.2

to the following portions designated with the black triangle to protect

parts and product from unusual abrasion.

Fig. 1

Item No.

Description

Gear housing

4g

a little

a little

a little

Gear room where Helical gear 37 rotates

Cam portion

Hole where Steel ball 3.5 and Pin 4 are assembled

Where Ball bearing 6002DDW touches drum portion

(when using in Hammer drill mode)

Cam housing complete

Spindle

Steel ball 3.5

Retaining ring WR12

Viewing from

Helical gear 37 side

Retaining ring R-32

Pin 4

Amount

Portion to lubricate

1R035

1R037

1R139

1R223

1R224

1R258

1R269

1R283

1R298

Bearing setting plate 15.2

holding spindle when assembling Helical gear 37

Bearing setting plate 20.2

holding Gear housing when removing Spindle

holding Gear housing cover when assembling Cam

Drill chuck extractor

fixing Spindle, when Drill Chuck removing

Torque wrench shaft 20-90N.m

removing / assembling Drill chuck

removing Ball bearings

Ratchet head 12.7 (For 1R223)

V block

Bearing extractor

Round bar for arbor 9-50

removing Spindle from Helical gear 37

Hex bar 10 with square socket

Helical gear 37

Ball bearing 6002DDW

7a

7b

7a

7b

R

epair