19 ENGLISH

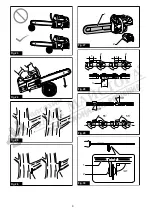

1.

Remove the sprocket cover and saw chain from

the tool.

2.

Remove the small dust or particles using a slotted

screwdriver or the like.

►

Fig.35:

1.

Slotted screwdriver

2.

Oil discharge hole

3.

Insert the battery cartridge into the tool. Pull the

switch trigger to flow built-up dust or particles off the oil

discharge hole by discharging chain oil.

4.

Remove the battery cartridge from the tool.

Reinstall the sprocket cover and saw chain on the tool.

Replacing the sprocket

CAUTION:

A worn sprocket will damage a

new saw chain. Have the sprocket replaced in this

case.

Before fitting a new saw chain, check the condition of

the sprocket.

►

Fig.36:

1.

Sprocket

2.

Areas to be worn out

Always fit a new locking ring when replacing the sprocket.

►

Fig.37:

1.

Locking ring

2.

Sprocket

NOTICE:

Make sure that the sprocket is installed

as shown in the figure.

Storing the tool

1.

Clean the tool before storing. Remove any chips and

sawdust from the tool after removing the sprocket cover.

2.

After cleaning the tool, run it under no load to lubri-

cate the saw chain and guide bar.

3.

Cover the guide bar with the guide bar cover.

4.

Empty the oil tank.

Instructions for periodic maintenance

To ensure long life, prevent damage and ensure the full functioning of the safety features, the following maintenance

must be performed regularly. Warranty claims can be recognized only if this work is performed regularly and prop-

erly. Failure to perform the prescribed maintenance work can lead to accidents! The user of the chain saw must not

perform maintenance work which is not described in the instruction manual. All such work must be carried out by our

authorized service center.

Check item / Operating time

Before

operation

Everyday

Every week

Every 3

month

Annually

Before

storage

Chain saw

Inspection.

-

-

-

-

-

Cleaning.

-

-

-

-

-

Check at

authorized

service center.

-

-

-

-

Saw chain

Inspection.

-

-

-

-

-

Sharpening if

necessary.

-

-

-

-

-

Guide bar

Inspection.

-

-

-

-

Remove from

the chain saw.

-

-

-

-

-

Chain brake

Check the

function.

-

-

-

-

-

Have it

inspected

regularly at

authorized

service center.

-

-

-

-

-

Chain

lubrication

Check the oil

feed rate.

-

-

-

-

-

Switch trigger

Inspection.

-

-

-

-

-

Lock-off lever

Inspection.

-

-

-

-

-

Oil tank cap

Check

tightness.

-

-

-

-

-

Chain catcher Inspection.

-

-

-

-

-

Screws and

nuts

Inspection.

-

-

-

-

-

Содержание UG002G

Страница 2: ...2 Fig 1 3 1 2 5 6 11 12 14 7 8 9 10 16 17 19 15 13 4 18 Fig 2 ...

Страница 3: ...3 1 1 2 3 Fig 3 1 2 Fig 4 1 2 Fig 5 2 1 Fig 6 3 2 1 2 3 Fig 7 2 1 Fig 8 ...

Страница 4: ...4 1 Fig 9 2 3 1 Fig 10 1 Fig 11 2 1 Fig 12 1 4 2 3 4 Fig 13 1 Fig 14 1 2 Fig 15 1 Fig 16 ...

Страница 5: ...5 3 2 1 Fig 17 1 Fig 18 1 2 Fig 19 1 2 3 Fig 20 1 2 Fig 21 Fig 22 ...

Страница 6: ...6 Fig 23 Fig 24 1 2 Fig 25 Fig 26 2 1 Fig 27 2 2 1 1 3 1 Fig 28 30 30 55 55 Fig 29 1 2 Fig 30 ...

Страница 7: ...7 30 1 5 1 Fig 31 Fig 32 Fig 33 Fig 34 1 2 Fig 35 1 2 Fig 36 1 2 Fig 37 ...