P 2/ 14

R

epair

Apply Makita grease to the following portions designated with the black triangle and the gray triangle to protect parts

and product from unusual abrasion.

[1] NECESSARY REPAIRING TOOLS

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

Code No.

Description

Use for

1R028

Bearing setting pipe 20-12.2

mounting Gear housing cover to Armature

1R045

Gear extractor (Large)

separate Armature from Gear housing cover

1R232

Pipe 30

removing Coupling and Ball bearing 6903ZZ from large Spiral bevel gear

1R258

V block

supporting Armature and Bearing box

1R268

Spring pin extractor M3

disassembling Shaft lock mechanism

1R269

Bearing extractor

removing Ball bearings 627DDW/ 696ZZ from Armature

1R281

Round bar for Arbor 7-50

removing Switch knob from Switch lever

1R286

Round bar for Arbor 12-50

removing large Spiral bevel gear section from Bearing box

1R291

Retaining ring S & R pliers

removing Retaining ring S-9

1R340

Bearing retainer wrench

removing Bearing retainer 20-33 from Bearing box

1R350

Ring 60

supporting Gear housing when disassembling Shaft lock mechanism

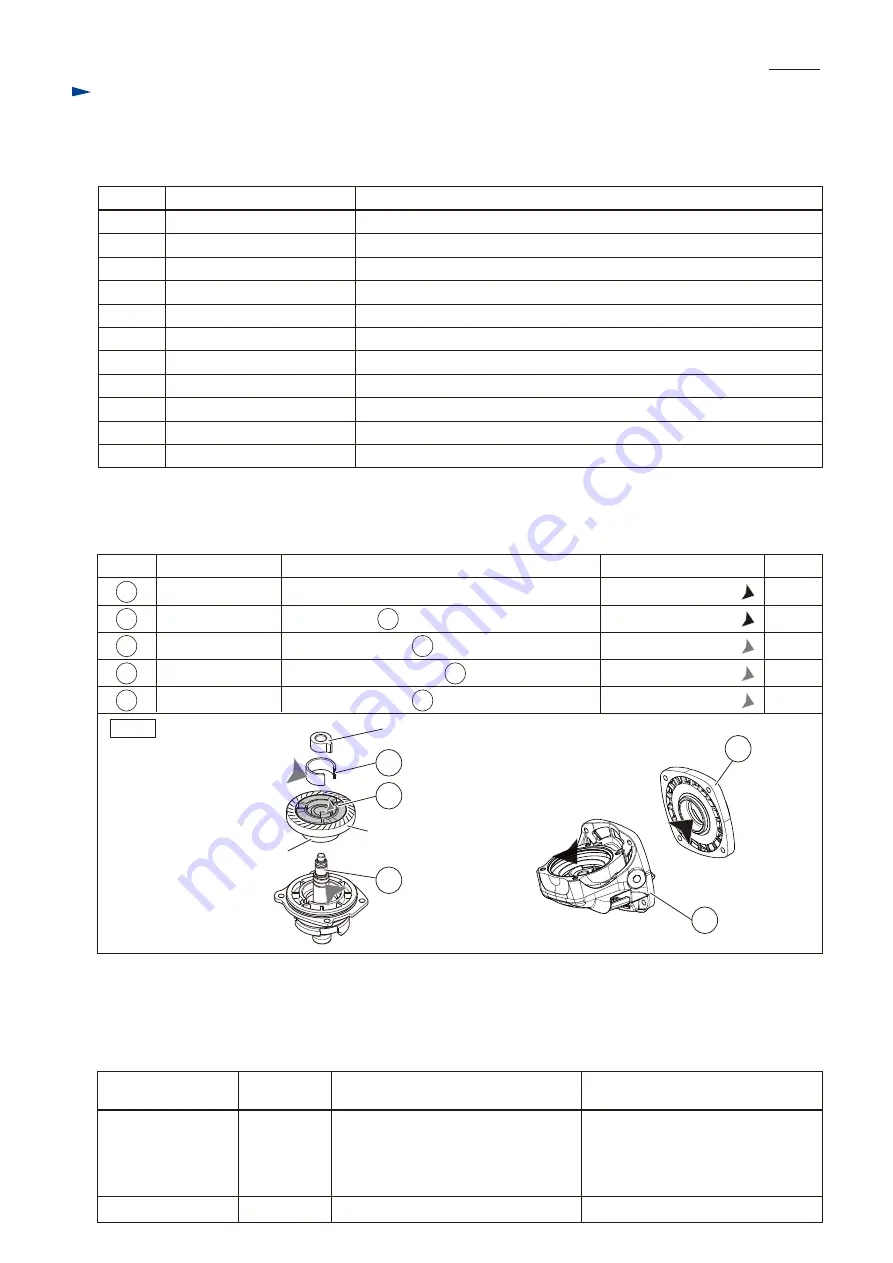

[2] LUBRICATION

Fig. 1

Item No.

Description

Gear housing

Gear housing cover

Lubricant

Amount

Portion to lubricate

Coupling

Spindle

Model No.

GA4041 GA4541C

GA4541 GA5041C

GA5041 GA4543C

GA4041C GA5043C

GA4043C

GA6041

Smaller spiral bevel gear

(on armature shaft)

Larger spiral bevel gear

(on spindle)

10 teeth

38 teeth

9 teeth

41 teeth

Gear room

17g

a little

a little

a little

70

56

Joint sleeve

Note

: As listed below, the grinders use different spiral bevel gears, and they are not interchangeable.

Referring to this list, therefore, be sure to use correct gears for replacement.

Spiral bevel gear (large)

Ball bearing 6903ZZ

6

58

58

O-ring 27.5 of 6 Gear housing cover

Drum portion where 58 Coupling contacts

Cylindrical portion where 56 C-type plate contacts

C-type plate

a little

56

Outer surface where 58 Coupling contacts

Makita Grease FA No. 2:

Makita Grease FA No. 2:

Makita Grease FA No. 2:

Makita Grease SG No. 0:

Makita Grease SG No. 0:

1

70

[3] DISASSEMBLY/ASSEMBLY

[3] -1. Note in Disassemble (general)

No load

speed: min.

ˉ

¹

11,000

9,000

6

1