10

ENGLISH

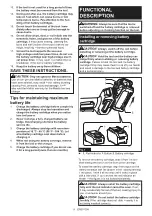

Indicating the remaining battery capacity

Press the check button on the battery cartridge to indi

-

cate the remaining battery capacity. The indicator lamps

light up for a few seconds.

1

2

Fig.2

►

1.

Indicator lamps

2.

Check button

Indicator lamps

Remaining

capacity

Lighted

Off

Blinking

75% to 100%

50% to 75%

25% to 50%

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

NOTE:

Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

NOTE:

The first (far left) indicator lamp will blink when

the battery protection system works.

Tool / battery protection system

The tool is equipped with a tool/battery protection sys

-

tem. This system automatically cuts off power to the

motor to extend tool and battery life. The tool will auto

-

matically stop during operation if the tool or battery is

placed under one of the following conditions:

Overload protection

When the tool/battery is operated in a manner that

causes it to draw an abnormally high current, the tool

automatically stops without any indication. In this sit

-

uation, turn the tool off and stop the application that

caused the tool to become overloaded. Then turn the

tool on to restart.

Overheat protection

When the tool/battery is overheated, the tool stops

automatically. Let the tool cool down before turning the

tool on again.

Overdischarge protection

When the battery capacity is not enough, the tool stops

automatically. In this case, remove the battery from the

tool and charge the battery.

Releasing protection lock

When the protection system works repeatedly, the tool

is locked.

In this situation, the tool does not start even if turning

the tool off and on. To release the protection lock,

remove the battery, set it to the battery charger and wait

until the charging finishes.

Protections against other causes

Protection system is also designed for other causes

that could damage the tool and allows the tool to stop

automatically. Take all the following steps to clear the

causes, when the tool has been brought to a temporary

halt or stop in operation.

1. Turn the tool off, and then turn it on again to

restart.

2. Charge the battery(ies) or replace it/them with

recharged battery(ies).

3. Let the tool and battery(ies) cool down.

If no improvement can be found by restoring protection

system, then contact your local Makita Service Center.

Shaft lock

WARNING:

Never actuate the shaft lock when

the spindle is moving.

It may cause serious injury or

the tool damage.

Press the shaft lock to prevent spindle rotation when

installing or removing accessories.

1

Fig.3

►

1.

Shaft lock