P 7 / 8

R

epair

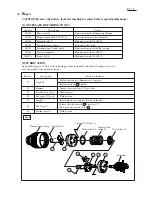

[3] -4. Hammer Mechanism and Spindle Section (cont.)

DISASSEMBLING

Fig. 19

Fig. 20

5) Now Hammer mechanism can be disassembled as illustrated in Fig. 19.

6) After removal of Flat washer 24, twenty-four 3.5 Steel balls can be removed from Hammer. (Fig. 20)

Spur gear 22

Flat washer 12

Pin 5

Hammer

Hammer

Compression

spring 25

Cup

washer 14

Steel ball 3.5

(24 pcs.)

Spindle

Flat washer 24

Spindle section

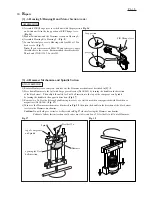

ASSEMBLING

Fig. 21

Hammer

1) Put twenty-four 3.5 Steel balls into the groove of Hammer. (Fig. 21)

Note: As illustrated to right in Fig. 21, the groove is designed to have a space equivalent to one 3.5 Steel ball

when twenty-four 3.5 Steel balls are correctly installed.

2) Then do the reverse of the disassembling steps.

Hammer

Steel ball 3.5

(24 pcs)

space equivalent to

one 3.5 Steel ball

Steel ball 3.5 (24 pcs)