P 3 / 8

R

epair

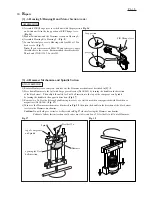

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Hammer Case Complete

Fig. 3

Fig. 4

Fig. 5

DISASSEMBLING

Note: You need not remove the Bit holder section

1) Remove PT3x10 Tapping screw, and pull LED circuit out of Housing. Remove Stopper by removing PT3x16

Tapping screw. Then remove Bumper from Hammer case complete. (Fig. 3)

2) Fix the machine in vise, and remove Hammer case complete by turning clockwise with three repair tools

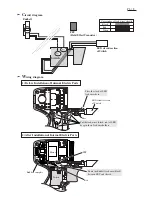

as illustrated in Fig. 4.

3) The machine can now be disassembled as illustrated in Fig. 5.

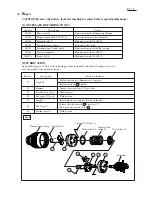

[3] -1. Bit Holder Section

DISASSEMBLING

See Fig. 2.

1) Remove Ring spring 11 from the groove on Anvil M

using Retaining ring S and R pliers (No.1R291).

2) Now the following parts can be removed from Anvil M:

Flat washer 12, Compression spring 13,

Sleeve, Steel ball 3.5 (2pcs)

ASSEMBLING

Do the reverse of the disassembling steps.

Note: Before putting Sleeve through Anvil, apply grease

to Anvil as described in [2] LUBRICATION.

Torque wrench shaft 20-90N.m

(No.1R223)

Ratchet head 12.7

(No.1R224)

Socket 30-78

(No.134847-1)

Hammer case comp.

Fig. 2

Ring spring 11

Flat washer 12

Compression spring 13

Anvil

Steel ball 3.5 (2pcs)

Sleeve

groove

Tapping screw PT3x10

Tapping screw

PT3x16

LED circuit

of Switch unit

Stopper

Bumper

Fit Socket 30-78

to the hex portion

of Hammer case

complete.

Hammer case comp.

Ring 41

Internal gear 51

Internal gear case

O ring 46

Assembly of Anvil

and Bit holder section

Hammer mechanism