Next, the air release valves, located in the top oil filler caps, should be checked by compressing forks and

observing air pressure release. The fork should return to its original position. If this is not the case, one

must countersink the seating of the ball (for the air release valve) lightly, (app. 150°- 160°). The surface

should have no grooves. Otherwise the ball should be tapped into the seat lightly. During re-assembly of

the forks, care must be taken that there is no pressure on the fork tubes or sliders after re-tightening

the

fork pinch bolts and the front axle.

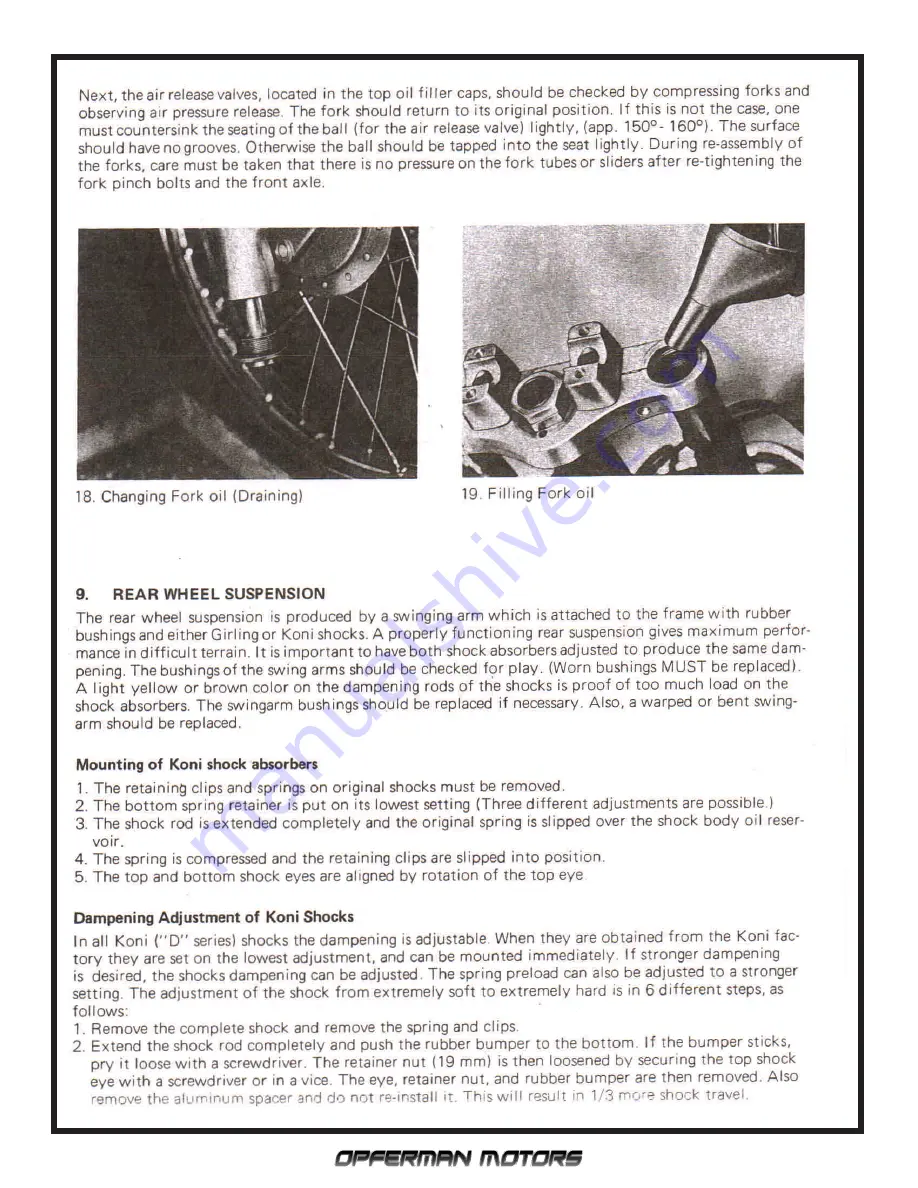

18. Changing Fork oil (Draining)

19. Filling Fork oil

-

9.

REAR WHEEL SUSPENSION

The rear wheel suspension is produced by a swinging arm which is attached to the frame with rubber

bushings and either Girling or Koni shocks. A properly functioning

rear suspension gives maximum perfor-

mance in difficult

terrain. It is important

to have both shock absorbers adjusted to produce the same dam-

pening. The bushings of the swing arms should be checked for play. (Worn bushings MUST be replaced).

A Iight yellow or brown color on the dampening rods of the shocks is proof of too much load on the

shock absorbers. The swingarm bushings should be replaced if necessary. Also, a warped or bent swing-

arm should be replaced.

Mounting of Koni shock absorbers

1. The retainin9 clips and springs on original shocks must be removed.

2. The bottom spring retainer is put on its lowest setting (Three different

adjustments are possible.)

3. The shock rod is extended completely

and the original spring is slipped over the shock body oil reser-

voir.

4. The spring is compressed and the retaining clips are slipped into position.

5. The top and bottom shock eyes are al igned by rotation of the top eye

Dampening Adjustment of Koni Shocks

In all Koni ("0"

series) shocks the dampening is adjustable. When they are obtained from the Koni fac-

tory they are set on the lowest adjustment,

and can be mounted immediately.

If stronger dampening

is desired, the shocks dampening can be adjusted. The spring preload can also be adjusted to a stronger

setting. The adjustment of the shock from extremely soft to extremely hard is in 6 different

steps, as

follows:

1. Remove the complete shock and remove the spring and clips.

2. Extend the shock rod completely

and push the rubber bumper to the bottom.

If the bumper sticks,

pry it loose with a screwdriver. The retainer nut (19 mm) is then loosened by securing the top shock

eye with a screwdriver or in a vice. The eye, retainer nut, and rubber bumper are then removed. Also

remove the alurnlnum spacer and do not rB-lnstall it. This will result in 1/.3

me",?

shock travel.

Next, the air release valves, located in the top oil filler caps, should be checked by compressing forks and

observing air pressure release. The fork should return to its original position. If this is not the case, one

must countersink the seating of the ball (for the air release valve) lightly, (app. 150°- 160°). The surface

should have no grooves. Otherwise the ball should be tapped into the seat lightly. During re-assembly of

the forks, care must be taken that there is no pressure on the fork tubes or sliders after re-tightening

the

fork pinch bolts and the front axle.

18. Changing Fork oil (Draining)

19. Filling Fork oil

-

9.

REAR WHEEL SUSPENSION

The rear wheel suspension is produced by a swinging arm which is attached to the frame with rubber

bushings and either Girling or Koni shocks. A properly functioning

rear suspension gives maximum perfor-

mance in difficult

terrain. It is important

to have both shock absorbers adjusted to produce the same dam-

pening. The bushings of the swing arms should be checked for play. (Worn bushings MUST be replaced).

A Iight yellow or brown color on the dampening rods of the shocks is proof of too much load on the

shock absorbers. The swingarm bushings should be replaced if necessary. Also, a warped or bent swing-

arm should be replaced.

Mounting of Koni shock absorbers

1. The retainin9 clips and springs on original shocks must be removed.

2. The bottom spring retainer is put on its lowest setting (Three different

adjustments are possible.)

3. The shock rod is extended completely

and the original spring is slipped over the shock body oil reser-

voir.

4. The spring is compressed and the retaining clips are slipped into position.

5. The top and bottom shock eyes are al igned by rotation of the top eye

Dampening Adjustment of Koni Shocks

In all Koni ("0"

series) shocks the dampening is adjustable. When they are obtained from the Koni fac-

tory they are set on the lowest adjustment,

and can be mounted immediately.

If stronger dampening

is desired, the shocks dampening can be adjusted. The spring preload can also be adjusted to a stronger

setting. The adjustment of the shock from extremely soft to extremely hard is in 6 different

steps, as

follows:

1. Remove the complete shock and remove the spring and clips.

2. Extend the shock rod completely

and push the rubber bumper to the bottom.

If the bumper sticks,

pry it loose with a screwdriver. The retainer nut (19 mm) is then loosened by securing the top shock

eye with a screwdriver or in a vice. The eye, retainer nut, and rubber bumper are then removed. Also

remove the alurnlnum spacer and do not rB-lnstall it. This will result in 1/.3

me",?

shock travel.

Maico 72-74.5 Radial Manaual

www.maicowerk.com

Courtesy of [email protected]