ADJUSTING BLADE TRACKING

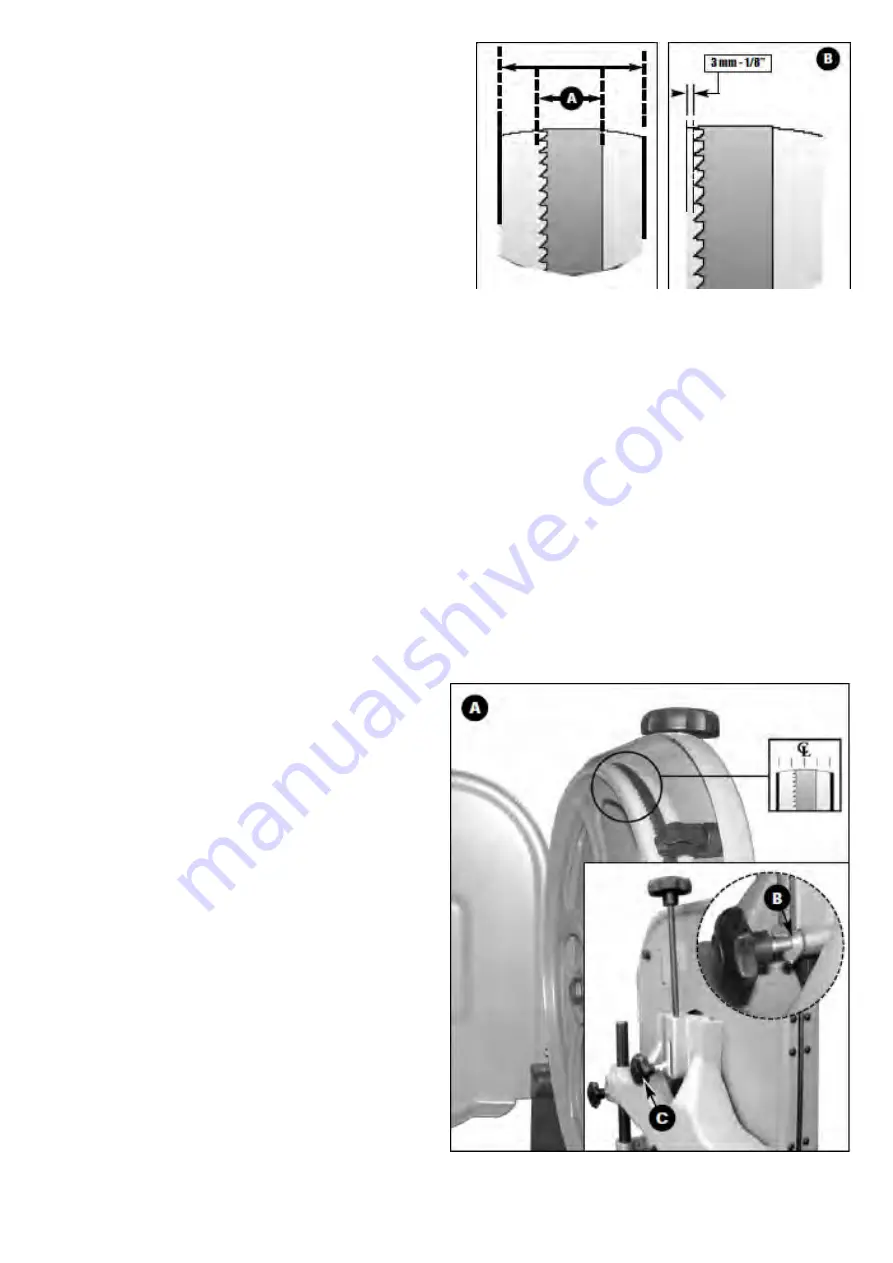

Blade tracking means centering the blade on the wheels A.

Ideally, the blade should stay relatively centered on both the

upper and lower wheels.

Due to natural variations in castings, blade thickness or density

and tire wear, absolute perfect centering alignment is

rarely attainable. A slight misalignment of the blade on the

wheels is inevitable and as long as it is kept to a minimum

(following the steps listed below) will not hinder the performance

of the saw.

This misalignment is controlled and kept to a minimum by adjusting the tilt angle of the upper wheel.

When adjusting blade tracking to center the blade on the wheels and assuming that perfect centering is not attainable,

it is preferable to have the blade slightly off-center towards the front of the wheels rather than towards the rear

because the teeth on most bandsaw blades have alternating hook (one inner, one outer) – therefore if the blade is

centered too far back on the wheel (or if the blade tension is too tight), inner hooked teeth will dig into the wheel

tire and cause premature wear of the tire.

Nonetheless, to avoid having the blade come off of the wheels on it’s own during operation, the front edge of the

blades teeth should never be any closer than 3 mm (1/8”) from the front edge of the wheel B.

BLADE CLEARANCE

Note: As previously stated, when performing blade installation, removal, tensioning or

tracking, maximum clearance between the blade and both upper and lower bearing assemblies

is required to minimize friction, which would be damaging to the blade. Refer back and follow

the instructions for “blade clearance” before performing blade tracking adjustments.

To adjust the blade tracking:

1. Open the upper wheel cover door then rotate the wheel

slowly forward by hand. The blade should remain as

centered as possible on the wheel as it turns A.

2. If the blade tracking must be adjusted, loosen thumb nut B,

then turn the tracking knob C, located on the rear of the

bandsaw:

a) Clockwise if the blade moves toward the front of the wheel.

This tilts the top of the wheel to the back and moves the

blade toward the center.

b) Counter-clockwise if the blade moves toward the back

edge. This tilts the top of the wheel to the front and moves

the blade toward the center.

Note: Turn the tracking knob in 1/2 turn

increments, recheck and adjust again as

needed.

3. Re-tighten thumb nut B

Содержание MI-91340

Страница 1: ...MODEL NO MI 91340 OPERATING MANUAL...

Страница 16: ...PART LIST FOR MI 91340...