2

Pneumatic switch

Max. supply pressure

Max. liquid temperature

Bleed orifice Ø

Code (NEMA 3R encl.)

description

bar (PSIG)

°C (°F)

mm (inches)

mat'l. code 1

mat'l. code 2, 4

Series J bleed type

6.9 bar (100 PSIG)

200°C (400°F)

1.60 mm (0.063")

JDG

JDE

4.1 bar (

1

60 PSIG)

200°C (400°F)

2.39 mm (0.094")

JEG

JEE

4.1 bar (

1

60 PSIG)

230°C (450°F)

1.40 mm (0.055")

JFG

JFE

Series K non bleed type

6.9 bar (100 PSIG)

200°C (400°F)

—

—

KOE

2.8 bar (

1

40 PSIG)

200°C (400°F)

—

KOG

—

SELECT ELECTRIC SWITCH MECHANISM & ENCLOSURE

➁

All models with material of construction code 1

All models with material of construction codes 2 and 4

NEMA 4X

NEMA 7/9

BASEEFA

CENELEC

NEMA 4X

NEMA 7/9

BASEEFA

CENELEC

cast aluminium

cast iron

cast iron

cast iron

cast aluminium

cast iron

cast iron

cast iron

Switch

1"

M 20

1"

M20

3/4"

M20

3/4"

1"

M 20

1"

M20

3/4"

M20

3/4"

Description

x

PG 16

x

x

x

PG 16

x

x

NPT

1.5

NPT

1.5

NPT

1.5

NPT

NPT

1.5

NPT

1.5

NPT

1.5

NPT

Series A –

230°C

SPDT

AAP

A2P

A3P

AKR

AK8

AU8

AK7

AU7

AAQ

A2Q

A3Q

AKY

AK6

AU6

AK5

AU5

Mercury switch

(450°F)

DPDT

ADP

A8P

A9P

ANR

AN8

AX8

AD7

AW7

ADQ

A8Q

A9Q

ANY

AN6

AX6

AD5

AW5

Series B –

120°C

SPDT

BAP

B2P

B3P

BKR

BK8

BU8

BK7

BU7

BAQ

B2Q

B3Q

BKY

BK6

BU6

BK5

BU5

Snap switch

(250°F)

DPDT

BDP

B8P

B9P

BNR

BN8

BX8

BD7

BW7

BDQ

B8Q

B9Q

BNY

BN6

BX6

BD5

BW5

Series C –

230°C

SPDT

CAP

C2P

C3P

CKR

CK8

CU8

CK7

CU7

CAQ

C2Q

C3Q

CKY

CK6

CU6

CK5

CU5

Snap switch

(450°F)

DPDT

CDP

C8P

C9P

CNR

CN8

CX8

CD7

CW7

CDQ

C8Q

C9Q

CNY

CN6

CX6

CD5

CW5

Series D –

120°C

Snap switch

(250°F)

SPDT

–

–

–

–

–

–

–

–

DAQ

D2Q

D3Q

DKY

DK6

DU6

DK5

DU5

for DC

DPDT

–

–

–

–

–

–

–

–

DDQ

D8Q

D9Q

DNY

DN6

DX6

DD5

DW5

current appl.

Series E –

230°C

Vibration

(450°F)

SPDT

EAP

E2P

E3P

EKR

EK8

EU8

EK7

EU7

EAQ

E2Q

E3Q

EKY

EK6

EU6

EK5

EU5

resistant

DPDT

EDP

E8P

E9P

ENR

EN8

EX8

ED7

EW7

EDQ

E8Q

E9Q

ENY

EN6

EX6

ED5

EW5

mercury switch

Series F –

230°C

Snap switch

(450°F)

SPDT

FAP

F2P

F3P

FKR

FK8

FU8

FK7

FU7

FAQ

F2Q

F3Q

FKY

FK6

FU6

FK5

FU5

hermetically

DPDT

FDP

F8P

F9P

FNR

FN8

FX8

FD7

FW7

FDQ

F8Q

F9Q

FNY

FN6

FX6

FD5

FW5

sealed

Series HS –

230°C

Snap switch

(450°F)

SPDT

–

–

–

–

–

–

–

–

HM2

H7A

H6A

HS3

HB1

HB2

HB3

HB4

hermetically

sealed with

DPDT

–

–

–

–

–

–

–

–

HM6

H7C

H6C

HS7

HB5

HB6

HB7

HB8

terminal block

Series U –

120°C

SPDT

UAP

U2P

U3P

UKR

UK8

UU8

UK7

UU7

UAQ

U2Q

U3Q

UKY

UK6

UU6

UK5

UU5

Snap switch

(250°F)

DPDT

UDP

U8P

U9P

UNR

UN8

UX8

UD7

UW7

UDQ

U8Q

U9Q

UNY

UN6

UX6

UD5

UW5

Series W –

230°C

Snap switch

(450°F)

SPDT

WAP

W2P

W3P

WKR

WK8

WU8

WK7

WU7

WAQ

W2Q

W3Q

WKY

WK6

WU6

WK5

WU5

hermetically

DPDT

–

–

–

–

–

–

–

–

WDQ

W8Q

W9Q

WNY

WN6

WX6

WD5

WW5

sealed

Series X –

230°C

Snap switch

(450°F)

SPDT

XAP

X2P

X3P

XKR

XK8

XU8

XK7

XU7

XAQ

X2Q

X3Q

XKY

XK6

XU6

XK5

XU5

hermetically

DPDT

–

–

–

–

–

–

–

–

XDQ

X8Q

X9Q

XNY

XN6

XX6

XD5

XW5

sealed

Max.

process

temp.

°C (°F)

Cont.

one

per

encl.

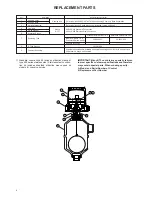

MODEL IDENTIFICATION

A complete B73 switch, consists of 1 code:

MATERIALS OF CONSTRUCTION

1

Carbon steel cage with 316 SST float and 400 SST magnetic sleeve.

2

Carbon steel cage with 316 SST float, magnetic sleeve with 316 SST jacket.

4

316 SST cage and trim and float.

B 7 3

complete code for

B73 liquid float level switch

Switch mechanism and enclosure, refer to table below for pneumatic switch mechanisms and for

electric switch mechanisms.

SIZE AND TYPE OF PROCESS CONNECTION

B

2 0

1" NPT threaded connection upper side/bottom

B

3 0

1" NPT socket weld connection upper side/bottom

➁

Housing heater and drain available in option. Consult factory for proper

model numbers.

③

Max. Process temperatures are based on 38°C (100°F) ambient tem-

perature.

SELECT PNEUMATIC SWITCH MECHANISM & ENCLOSURE

1" ANSI type

NW 25 DIN FORM C

(DIN 2526)

▼

FLANGE TYPE & SIZE

150 lbs

300 lbs

ND 16

(DIN 2533)

ND 25

(DIN 2534)

▼

MOUNTING STYLE

N30

N40

1FA

1GA

flanged connection upper side/bottom

S30

S40

1FB

1GB

flanged connection side/side

③

▼