1.

Remove the weight shelf. Remove nuts 1

and 2 with relative cup springs and washers.

2.

Back-off screws 3, 4 and 5 then disassemble

the various parts.

3.

Reassemble the various parts without

tightening the nuts being careful to follow

the correct sequence.

N.B. Mount the piezo units in accordance with the

position of the colored wires shown in the drawing.

4.

Keeping the spindle perfectly aligned,

tighten nut 5 with a spanner, and nuts 3 and

4 by hand (by half a turn with the spanner if

necessary).

5.

Refit the washers, cup springs and nuts 1

and 2. Tighten the nuts fully in order to fully

regain the elasticity of the cup springs, This will automatically ensure correct pre-loading on

the piezo (a torque wrench can be used set to 400kg·cm.).

6.

For correct operation, insulation of the piezo crystals should be greater than 50 M ohm.

7.

Reassemble the various parts. 8. Again carry out the automatic calibration.

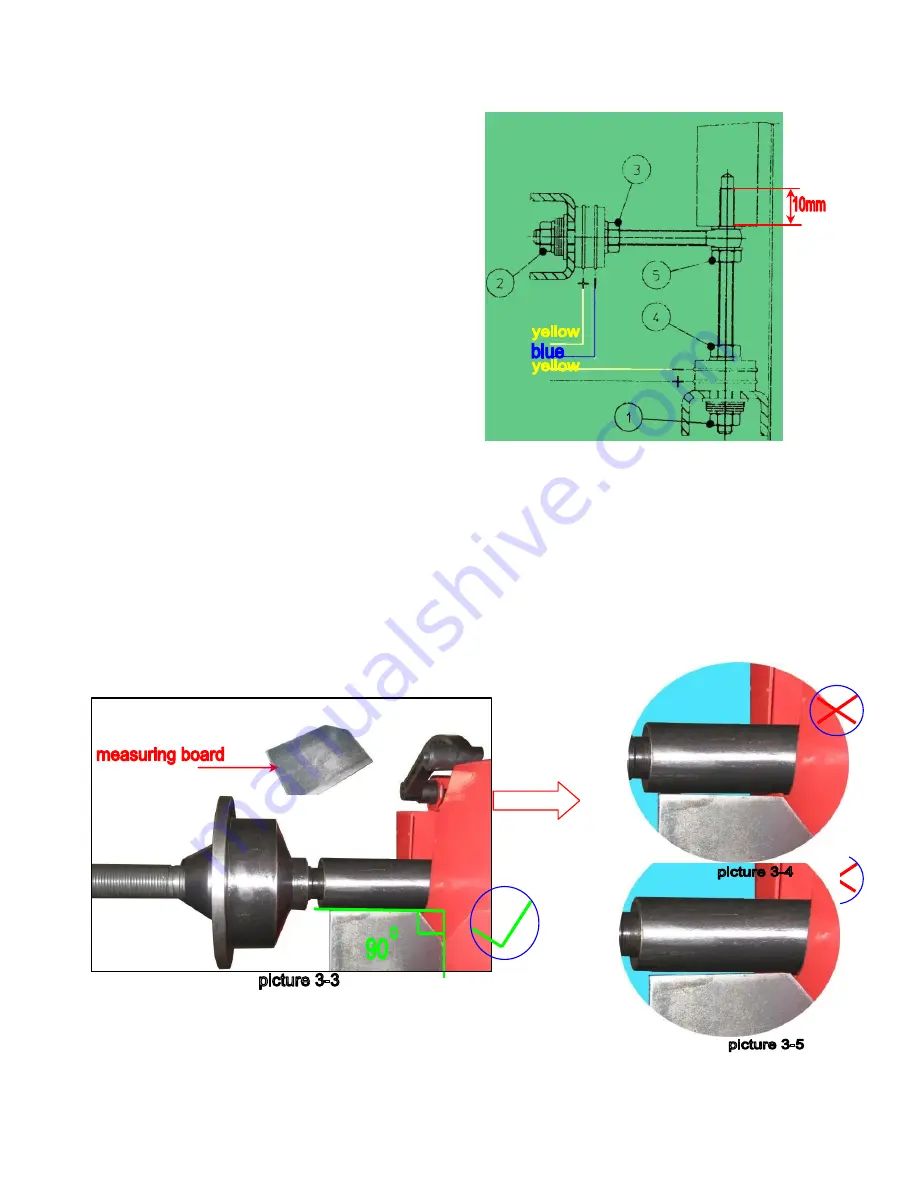

Must be confirmed that the complete shaft should perpendicular to the machine body before screw

down. Please see the following showed sketch picture 3-3, 3-4 and 3-5.