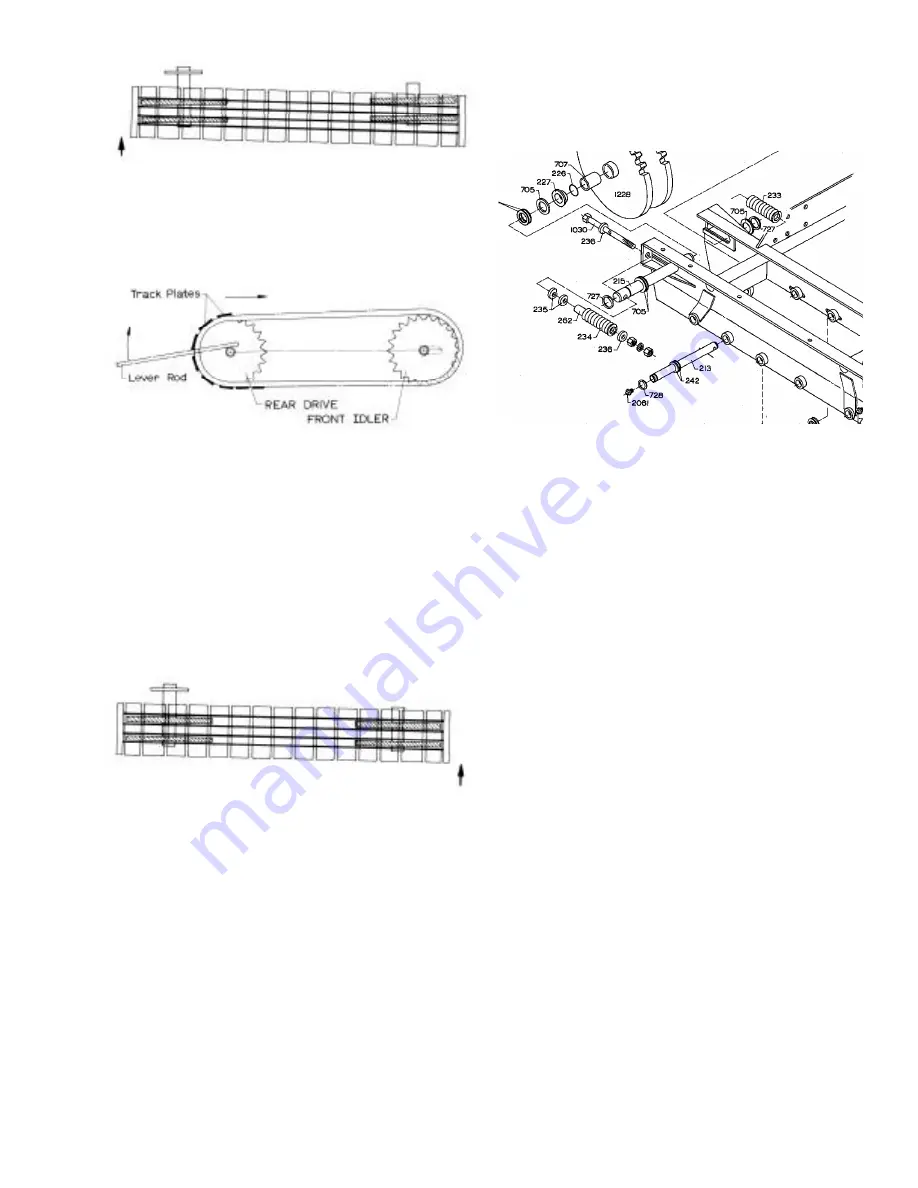

Reinsert Lever Rod and rotate the Tr a c k

forward

. Hold the above alignment and allow the

Sprocket’s teeth to enter their respective Track’s

Inner & Outer Chain. While rotating Tr a c k ,

remove all Track Rods as they drop free.

Continue rotating Track

f o r w a r d

w h i l e

inserting Track Rods into the alternate mating

teeth of the Front Idler’s Inner & Outer

Sprockets...keep Rods centered over their

respective Inner & Outer Sprockets.

When the last Track Rod inserted rotates to

the 12:00 o’clock position, remove the Lever Rod

and force the Track

inward

until the Track’s Inner

& Outer Chains align with their mating Inner &

Outer Sprockets on the Front Idler.

Rotate the Track

rearward

while holding the

above alignment and allow the Sprocket’s teeth to

engage their respective Inner & Outer Tr a c k

Chains. Remove all the Track Rods as they drop

free; save them for next time.

Replace the #234 Spring (black) by slipping it

over the end of its respective #1030 Rod (on

outside of Track) and over its #262 Tube, which

should still be in place on #1030 Rod. Secure

Spring with a #236 Washer followed by a 1/2” Nut

(fine thread).

In a similar manner replace the #233 Spring

(yellow) over its respective #1030 Rod & #262

Tube (on inside of Track)...secure with #236

Washer followed by 1/2” Nut (fine thread).

By rotating each #1030 Rod

clockwise

, draw

the 1/2” Nut & #236 Washer (on each Rod’s end)

against its respective #233 or #234 Spring such

that each Spring is compressed to a total length of

4.5”.

N O T E

: Tighten the pair of #233 & #234

Springs 1/4” at a time. Tighten the #234 Spring

(black) 1/4”, then stop and go to the #233 Spring

(yellow) and tighten it 1/4”. Work back and forth

from #234 Spring to #233 Spring 1/4” at a time

until

b o t h

Springs are 4.5” in total length.

Measure Spring length only...do not include the

#235 & #236 Washers in your measurement).

At this time, slowly and safely remove all

“support” blocking from underneath your Crawler

so that the Crawler rests firmly on only its Tracks.

Go on to the next section for instructions on Track

Tensioning.

TRACK TENSIONING

Before starting your tensioning procedure,

make sure your Track System is relatively clean

and free of debris...a high-pressure wash job is an

excellent idea.

Drive your Crawler through a “clean” area to

work out debris that may have lodged between

Track Sprocket teeth or in the Track’s Chain Links.

Park your Crawler on a firm level surface, shut off

engine and dismount.

On the side of the Track you are going to

tension, remove its respective #1220 Spring

Guard...save Cap Screws & Nuts for reassembly.

Remove the 1/2” Nut and 1/2” Lock Washer at

the extreme end of each #1030 Rod.