215593

70

Revision A

4.9.4

Adjusting Conditioner Roll Tension

The conditioner roll tension is maintained by two tension springs providing pressure for conditioning of the crop. These

springs also allow the rolls to open to allow passage of small solid objects without damage to the rolls.

DANGER

To avoid bodily injury or death from unexpected start-up or fall of a raised machine, always stop engine and remove

key before leaving the operator

’

s seat, and always engage safety props before going under the machine for any reason.

1.

Lower the header to the ground.

2.

Shut down the engine, and remove the key from

the ignition.

$

%

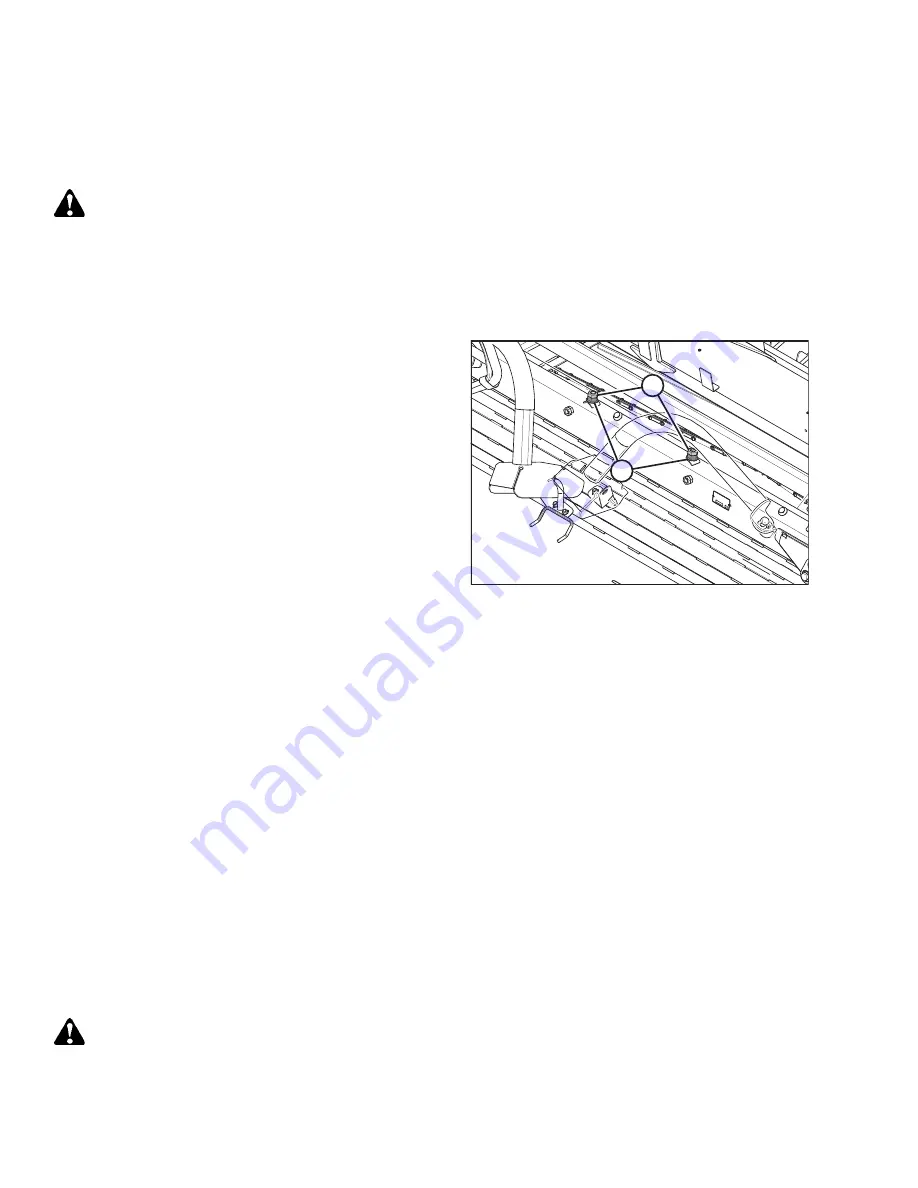

Figure 4.36: Conditioner Channel

3.

Locate adjustment nuts (B) on top of the conditioner

channel.

4.

Loosen jam nuts (A).

5.

Turn adjusting nut (B) clockwise to increase tension, and

counterclockwise to decrease tension.

6.

Adjust nuts (B) on both sides equal amounts.

7.

Tighten jam nuts (A).

4.9.5

Forming Shields

The position of the forming shields controls the width and placement of the windrow.

The position of the forming shields should be based on the following factors:

•

Weather conditions (rain, sun, humidity, wind)

•

Type and yield of crop

•

Drying time available

•

Method of processing (bales, silage, green-feed)

A wider windrow will generally dry faster and more evenly, resulting in less protein loss. Fast drying is especially important

in areas where the weather allows only a few days to cut and bale.

Where weather conditions permit or when drying is not critical (for example, when cutting for silage or green-feed), a

narrower windrow may be preferred for ease of pick-up.

Adjusting Forming Shield Height

The height of the forming shield affects the shape and consistency of the windrow. A heavy crop will require the forming

shield to be set near the highest position and a lighter crop needs the forming shield to be lower.

DANGER

To avoid injury or death from unexpected start-up of the machine, always stop the engine and remove the key from

the ignition before leaving the operator

’

s seat for any reason.

Содержание HC10

Страница 10: ...215593 viii Revision A Index 167 Predelivery Checklist 173 TABLE OF CONTENTS...

Страница 18: ......

Страница 84: ......

Страница 100: ......

Страница 103: ......

Страница 104: ...215593 94 Revision A 6 3 Lower Roll and Frame Assembly...

Страница 106: ...215593 96 Revision A 6 4 Upper Roll Assembly 0...

Страница 108: ...215593 98 Revision A 6 5 Cover and Supports 0 0 0 0 0 0...

Страница 110: ...215593 100 Revision A 0 0 0 0 0 0 REPAIR PARTS...

Страница 112: ...215593 102 Revision A 6 6 Hydraulic Motor Mounts and Tensioner Motor MD 159661...

Страница 114: ...215593 104 Revision A REPAIR PARTS...

Страница 116: ...215593 106 Revision A 6 7 Hydraulic Motor Mounts and Tensioner Motor MD 159648...

Страница 118: ...215593 108 Revision A REPAIR PARTS...

Страница 120: ...215593 110 Revision A 6 8 Belt Drive and Shield Motor MD 159661...

Страница 122: ...215593 112 Revision A 6 9 Belt Drive and Shield Motor MD 159648...

Страница 124: ...215593 114 Revision A 6 10 Hydraulic Completion Package Motor MD 159661...

Страница 126: ...215593 116 Revision A REPAIR PARTS...

Страница 128: ...215593 118 Revision A 6 11 Hydraulic Completion Package Motor MD 159648...

Страница 130: ...215593 120 Revision A REPAIR PARTS...

Страница 132: ...215593 122 Revision A 6 12 Gears and Roll Coupling Assembly New With Washer MD 30441...

Страница 134: ...215593 124 Revision A 6 13 Gears and Roll Coupling Assembly Old With Washer MD 130688...

Страница 136: ...215593 126 Revision A 6 14 Forming Shields...

Страница 138: ...215593 128 Revision A 6 15 Feed Deck and Pan 0 1...

Страница 140: ...215593 130 Revision A 0 1 REPAIR PARTS...

Страница 142: ...215593 132 Revision A 6 16 Mounting Brackets...

Страница 144: ......

Страница 156: ......

Страница 158: ......

Страница 168: ......

Страница 184: ......

Страница 185: ......