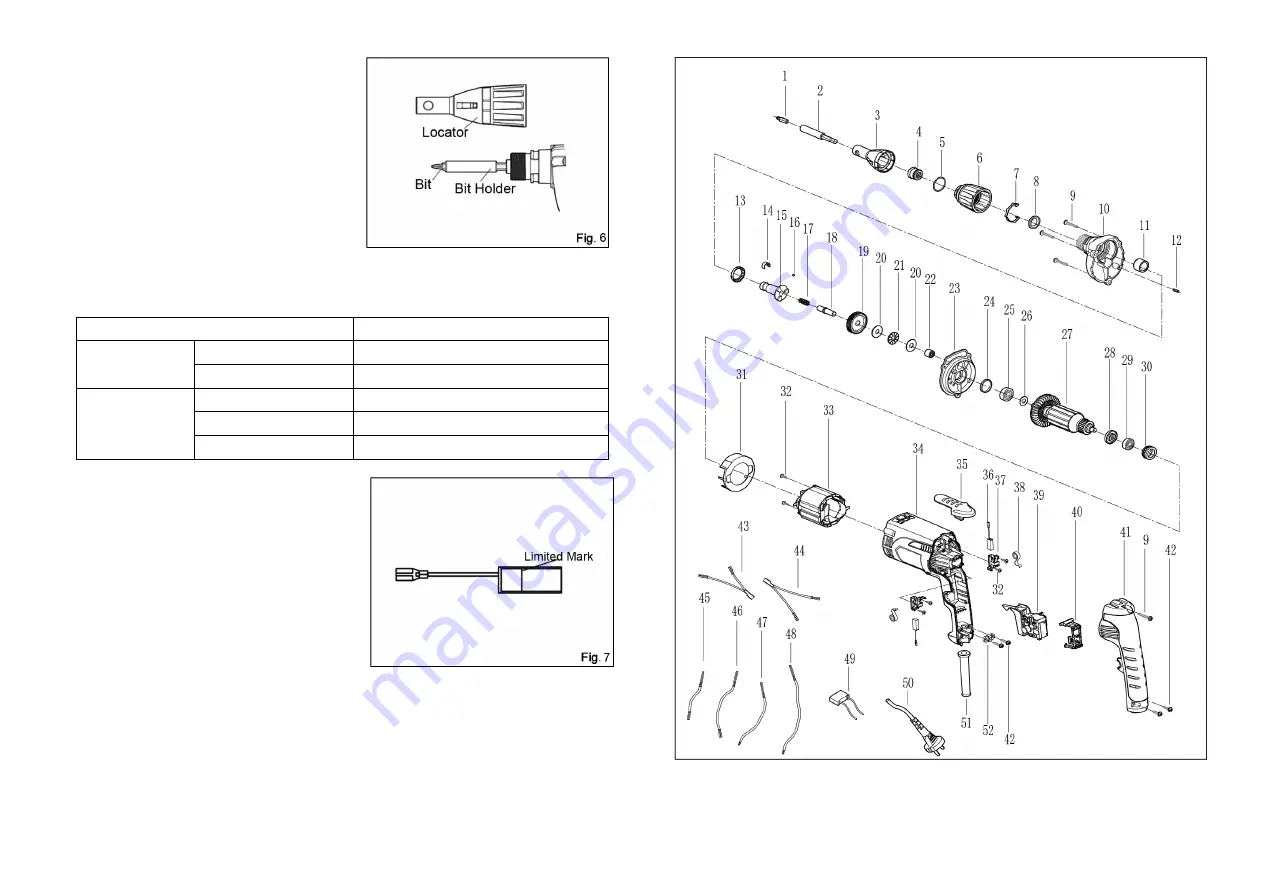

Grasp the bit with a pair of pliers and pull the bit

out of the magnetic bit holder. Then install the

locator by pushing it firmly back onto the gear

housing. (Fig. 6)

Matching of the Bit and Screw

Only the bit matches the groove of the Philips head can you tighten the screw properly. Please see

the following chart :

Bit No.

Standard Diameter (mm)

PH1

Wood Screw

2.1-2.7

Metal Screw

M2-M2.6

PH2

Wood Screw

3.2-4.8

Metal Screw

M3-M5.5

Wallboard Screw

NO. 6

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before attempting to perform inspection

or maintenance.

Replacing carbon brushes

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark.

Keep the carbon brushes clean and free to slip in the

holders. Both carbon brushes should be

replaced at the same time. Use only identical carbon brushes. (Fig. 7)

Maintenance of the Motor

The motor unit winding is the very “heart” of the power tool. Exercise due care to ensure the

winding does not become damaged and /or wet with oil or water.

Содержание SSCREW-001

Страница 1: ......