Servomotors

Servomotor 4-20 mA

21

© Lutz-Jesco GmbH 2017

Subject to technical changes.

170518

BA-20710-02-V05

Chlorine control valve

C 7700

Operating instructions

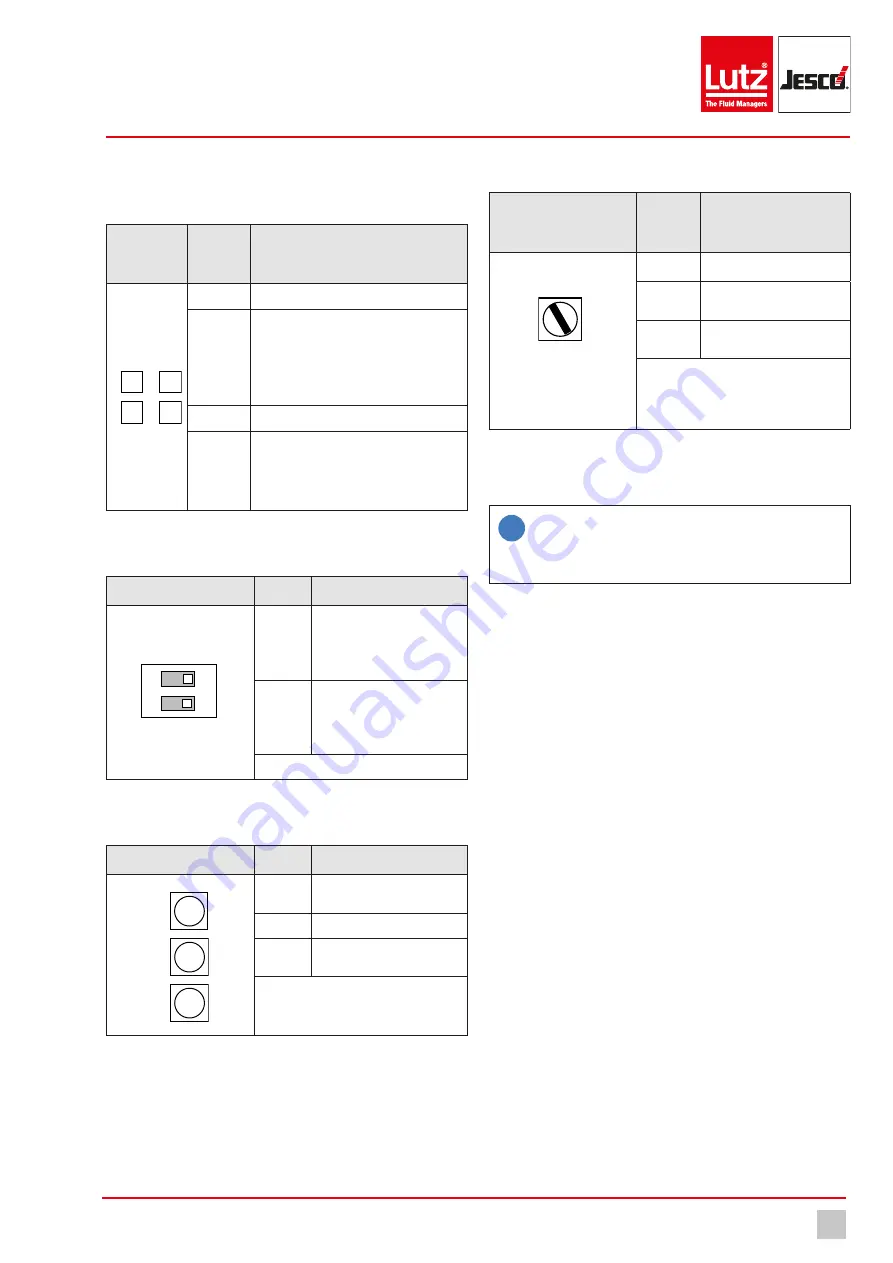

8.3.3 Operator controls of the servomotor

LEDs

LED

arrange-

ment

No.

(colour)

Meaning

R

L

4

3

2

1

1 (blue)

Operation

2 (red)

Fault

n

Voltage supply failure

n

Servomotor in manual operation

n

Current input below 2 mA

(if signal is 4-20 mA)

3 (yellow) Left-hand rotation active (close valve)

4 (green)

Right-hand rotation active (open valve)

Table 21: LED functions

DIP switch

Switch

Position

ON

1

2

1

Rotation direction of the

servomotor

left: 20 mA = valve closed

right: 20 mA = valve open*

2

Operating mode of the servo-

motor

Left: manual operation

Right: automatic operation*

* delivery state

Table 22: DIP switch functions

Keys

Arrangement

Key

Meaning

L

R

SET

L

Manual mode left-hand

rotation = close valve

SET

Program end position

R

Manual mode right-hand

rotation = open valve

The keys have no functions in automatic

mode

Table 23: Key functions

Hysteresis potentiometer

Direction

of

rotation

Position

Clockwise Increase hysteresis

Anti-

clockwise

Reduce hysteresis

R

Manual mode right-hand

rotation = open valve

The hysteresis is adjustable in the

0.1 - 2 mA range. If the setting is too

fine, the motor might run continuously

even with a stable input signal.

Table 24: Key functions

8.3.4 Programming the servomotor

i

The regulation bevel of the motor is 90° for a dosing capacity

of 0-100%. If the regulation bevel is greater, the feedback

potentiometer will shift during operation and the device will

not function reliably.

The servomotor is adjusted to a setting range of 0-100% in its delivery

state. A different setting is only useful in special cases.

Before you change anything on the servomotor, check if the counternut of

the adjusting spindle is tightened securely.

Perform the following working steps:

1.

Switch DIP switch 2 to manual operating mode.

2.

For a minimum and maximum dosing capacity, adjust the trigger

cams to the desired position. The rotary selector switches can be

adjusted by hand without tools.

4

Rotary selector switches adjusted.

3.

After adjusting the rotary selector switches, the motor must move to

both end positions. This allows the slip coupling of the potentiometer

to adjust itself. First, press the R button and keep it pressed until the

motor stops, then press the L button.

4

This adjusts the slip clutch on the potentiometer.

4.

Press and hold down the L key until the rotary selector switch turns

off the motor with the valve closed. Then release the L key.

5.

Press the SET key.

4

The blue LED flashes.

6.

Press the L key 1x within 3 s.

4

The blue LED turns off.

4

The end position 0% is programmed.

7.

Press and hold down the R key until the rotary selector switch turns

off the motor with the valve open. Then release the R key.

8.

Press the SET key.

4

The blue LED flashes.

9.

Press the R key 1x within 3 s.

4

The blue LED turns off.

4

The end position 100% is programmed.

inv.

Manu

Auto

Hyster.