29

Care and Maintenance

In order to maintain your machine in peak working order, it is necessary to carry out routine

maintenance. As pointed out in the Safety section of this manual, no other material than that

specified is to be compacted. These materials are as follows:

Cardboard, Paper, Plastic, Foam and Soft Materials.

A. Correct Maintenance and Inspection Procedures

a. Learn how to service your machine correctly

b. Follow the correct maintenance and inspection procedures shown in this

manual

c. Inspect machine daily before starting

d. Check for loose or missing parts

If there is a problem with your machine, contact LSM Engineering Ltd Service Dept.

B. Recommended Maintenance

The following is a maintenance list recommended to you by LSM Engineering Ltd to

ensure your machine is kept in peak condition. Due to its simplistic design, the V5HD

requires little maintenance.

Before any maintenance procedures are performed please ensure that the centre plate is

in the fully down position. This is for your safety and shall protect you in the event of a

hydraulic hose failing.

The following weekly maintenance is recommended:

a. Oil any door hinges or moving latches with WD40 / Grease.

b. Check tightness on all nuts and bolts after the first use and afterwards on a

weekly basis. If loose, contact the LSM Service Department for torque settings.

c. Check oil level and check for any oil leaks.

d. Keep machine clean.

e. Keep top of packing plate free of debris.

Use Only Hydraulic Oil of Types: HYD 32 or

68.

The motor has an oil fill level indicator on the tank

The motor is supplied with a sealed relief valve. ONLY

LSM personnel or their authorised dealers are allowed to

adjust this valve and will replace the seal if such work

has to be done.

Tampering with this seal may void your warranty.

Note

– Use only genuine LSM spare parts.

Note

– In order to maximise the life of your LSM Baler it should receive a full

service once a year. Contact the LSM Service Department or your local

distributor to arrange your service dates

Содержание V5HD

Страница 2: ...2 ...

Страница 4: ...4 ...

Страница 11: ...11 Safe Operation Zone Ejection ...

Страница 12: ...12 Emergency Stop Location ...

Страница 16: ...16 ...

Страница 18: ...18 ...

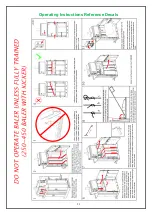

Страница 22: ...22 Operating Instructions Reference Decals ...

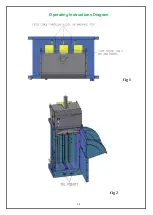

Страница 24: ...24 Operating Instructions Diagram fig 1 fig 2 ...

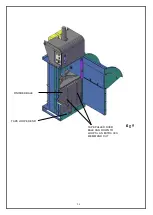

Страница 26: ...26 fig 5 FINISHED BALE TAPE PULLED OVER BALE AND DOWN TO LOOPS AN EXTRA 300 400MM AND CUT TAPE LOOPED END ...

Страница 30: ...30 V5HD BALER PARTS LIST ...

Страница 36: ...36 ...

Страница 38: ...38 ...

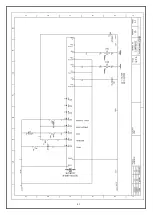

Страница 39: ...39 ELECTRICAL DIAGRAMS ...

Страница 40: ...40 ...

Страница 41: ...41 ...

Страница 42: ...42 ...

Страница 43: ...43 Electrical Diagram ...