SOMMAIRE

E 7

5.2 proof interval

According table 2 from CEI 61508-1 the PFDavg ,for systems operating in low demand mode,

must be between ≥ 10

-3

and <10

-2

for SIL2 safety functions and between ≥ 10

-4

and <10

-3

for SIL3 safety functions .

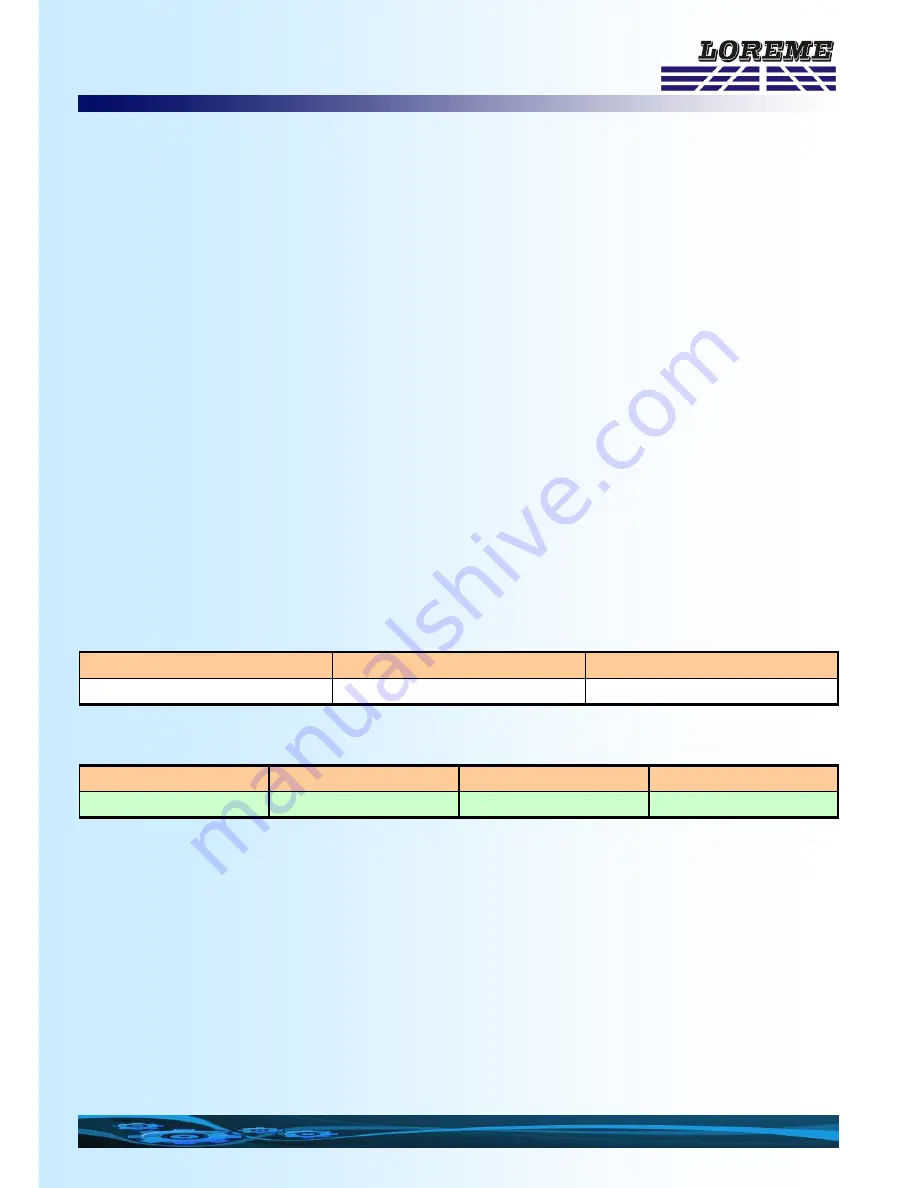

T

[Proof]

= 1 year

T

[Proof]

= 5 years

T

[Proof]

= 10 years

T

[Proof]

= 20 years

PFD

avg=7.88E

-06

PFD

avg=3.94E

-05

PFD

avg=7.88E

-05

PFD

avg=1.57E

-04

temperature conditions 45°C

PFD

avg

value depending proof interval

λ

safe

λdangerous = PFH

SFF

305 FIT

1.8 FIT

99.4%

approximation : PFDavg =

λdangerous x T[Proof] /2 (error caused by approximation < 3%)

Fields marked in green means that the calculated values of PFDavg are within the limits allowed for SIL 3

Summary:

Fault probability PFD = 7.88 E

-6

x Tproof [year]

either for : Tproof = 10 years 8 % from SIF and for Tproof = 20 years 16 % from SIF in SIL3

Remarks :

- Test intervals should be determined according to the PFDavg required .

- The SFF , PFDavg and PFH must be determined for the entire safety instrumented function (SIF)

ensuring that the " out of range current values" are detected at system level and they actually lead to the safety position.

5 Commissioning and periodic proof

The periodic test procedure is defined by LOREME and must be followed by the end user to ensure and guarantee the SIL level over

time.

Periodic testing should be performed following the procedure defined below and at the intervals defined

under paragraph

" proof interval "

5.1 control steps

Periodic proof allows detection of possible product internal failure and loop calibration.

environmental conditions and a minimum heating time of 5 minutes must be respected.

Isolator test and complete output Loop control (

the system is unavailable during the test

)

1. If necessary, bypass the security system and / or take appropriate provision to ensure safety during the test.

2. Disconnect the current input transmitter.

3. Using a current simulation device (note 1), set the input current to high alarm value (≥ 21.0 mA).

4. Raise the front cover of device. With the TEST terminals and a milliammeter, check if each output current have this value /-

1%. (the green LED of each output is light off when the milliammeter is connected)

5. Set the input current to the low alarm value (≤ 3.6 mA)

6. Check if the signal from each output reaches this value /-1%

7. Set the output current to a median value (= 12 mA)

8. Check if the signal from each output reaches this value at +/-1% (linearity and transfer function check)

9. Remove the input simulator, close the front panel and connect the transmitter input .

10. Remove the bypass on the safety controller system or return to a normal operating condition

11. After testing, the results should be documented and archived.

Any device that does not satisfy the control needs to be replaced.

Note 1: The current generator must be calibrated (according to the state of the art and practice)

4-20mA signal isolator, signal splitter with 2,3,4 outputs

SIL2 / SIL3

CAL4/100ig CAL4/100igM