- 26 -

Workshop Manual 12 LD _ cod. 1.5302.460 - 3° ed_ rev. 02

A

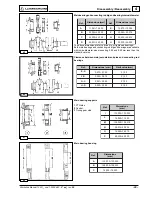

5

0

,

8

1

1

÷

5

9

,

7

1

1

C

5

2

0

,

2

2

÷

5

1

0

,

2

2

D

5

0

0

,

2

2

÷

5

9

9

,

1

2

D

-

C

3

0

,

0

÷

1

0

,

0

7

0

,

0

0

0

,

1

-

5

9

,

0

-

0

9

,

0

-

5

8

,

0

-

0

8

,

0

-

5

7

,

0

-

0

7

,

0

-

5

6

,

0

-

0

6

,

0

-

5

5

,

0

-

0

5

,

0

-

5

4

,

0

29

30

31

32

33

34

35

4

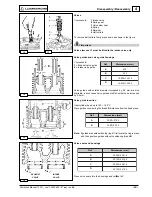

Piston - Refitting

Connect piston to connecting rod in a way that the combustion

chamber center b is at right angle under nozzle tip a.

Lubricate piston pin and introduce it into the piston by exerting

pressure with your thumb.

Check that both circlips are well inside their seats.

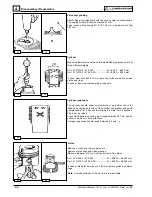

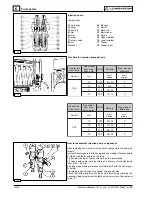

(with machine bushing in place)

limit of wear

Piston clearance

A = Piston clearance = 0,65÷0,70 mm

0,55÷0,60 mm for EPA engines

B = Copper head gasket

A is determined by placing the piston at top dead center and

measuring, with a feeler gauge and straight edge, the distance the

piston is below or above the cylinder face.

A copper gasket B (available in various thicknesses) is then selected

to ensure the clearance is correct.

Gaskets are available in the following thicknesses:

Connecting rod small end bushing

Dimensions and clearance (mm):

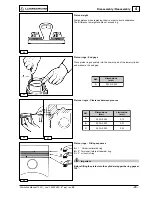

Connecting rod big end bearing

Both centering notches A and B must be on the same side when

refitting.

Tighten bolts to 40 Nm.

See page 29 for dimensions.

Disassembly / Reassembly