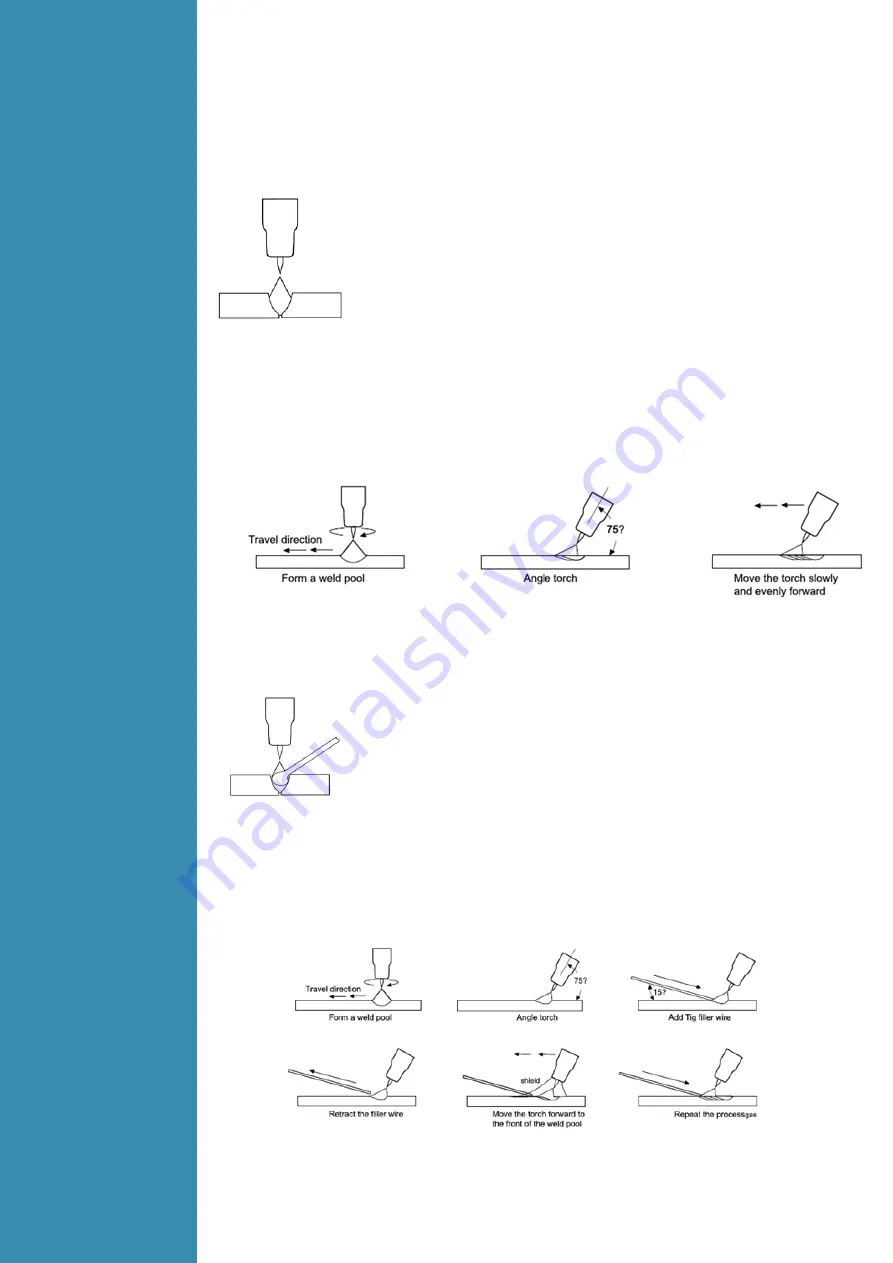

TIG Welding Fusion Technique

Manual TIG welding is often considered the most difficult of all the welding

processes. Because the welder must maintain a short arc length, great care and

skill are required to prevent contact between the electrode and the work piece.

Similar to Oxygen Acetylene torch welding, Tig welding normally requires two

hands and in most instances requires the welder to manually feed a filler wire

into the weld pool with one hand while manipulating the welding torch in the

other. However, some welds combining thin materials can be accomplished

without filler metal like edge, corner, and butt joints. This is known as Fusion

welding where the edges of the metal pieces are melted together using only

the heat and arc force generated by the TIG arc. Once the arc is started the

torch tungsten is held in place until a weld pool is created, a circular movement

of the tungsten will assist is creating a weld pool of the desired size. Once the

weld pool is established tilt the torch at about a 75° angle and move smoothly

and evenly along the joint while fusing the materials together.

TIG Welding with Filler Wire Technique

It is necessary in many situations with TIG welding to add a filler wire into the

weld pool to build up weld reinforcement and create a strong weld. Once

the arc is started the torch tungsten is held in place until a weld pool is

created, a circular movement of the tungsten will assist is creating a weld

pool of the desired size. Once the weld pool is established tilt the torch at

about a 75° angle and move smoothly and evenly along the joint. The filler

metal is introduced to the leading edge of the weld pool. The filler wire is

usually held at about a 15° angle and fed into the leading edge of the

molten pool, the arc will melt the filler wire into the weld pool as the torch is

moved forward. Also a dabbing technique can be used to control the amount of filler wire added, the

wire is fed into the molten pool and retracted in a repeating sequence as the torch is moved slowly and

evenly forward. It is important during the welding to keep the molten end of the filler wire inside the

gas shield as this protects the end of the wire from being oxidised and contaminating the weld pool.

Содержание GRAND TIG 200 DC PFC MV

Страница 20: ...4 4 Electrical schematic drawing ...