Owner’s Manual (Hydraulic Flail Mower)

N14800 3 - August, 2004

1

Maintenance

Lubrication:

The operation and component lifetimes of this

machine are very dependent on regular and proper

lubrication. The frequency of lubrication

recommended is based on normal conditions.

Severe or unusual conditions may determine actual

service requirements.

Replace any broken or missing grease fittings. Be

sure to clean fittings before greasing

.

NOTE:

Rotor, roller, and line shaft bearings

cannot be damaged by over-greasing. Grease

bearings until a small amount of grease is purged

from the bearing.

The following items require lubrication every (8)

hours of running time:

A)

Rotor bearings - located on each end of

machine and on the driveline side,

located under belt cover.

B) Roller bearings - located on each end of

roller.

C) Universal joint - located on left side of

the drive motor, under driveline shield.

The following items require lubrication every (25)

hours of running time:

A)

Belt idler bracket - located under belt

cover.

General Service

When reassembling components, always use new

lock nuts and a thread-locking compound to insure

against vibration loosening. Use an anti-seize

compound on all bearing/shaft contacts.

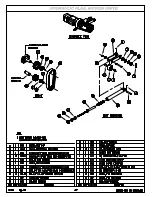

Procedure for Adjusting Height of Cut:

This procedure should be performed on a level

surface with mower mounted on tractor

.

The Loftness Flail Mower uses slotted adjustments

on the rear roller to allow an infinite cutting height

adjustment from 0 to 4-1/2”. To adjust the height

of cut:

1) Set bucket tilt cylinders to carry flail

mower level from front to rear.

2) Manually position knife rotor until the

bottom row of knives is at the lowest

operating position.

3)

Set blocks under skid shoes at the desired

cutting height.

4)

Loosen the nuts of the 5/8” carriage bolt

and the 5/8” pivot bolt, on both sides of

the mower.

5) Allow steel roller to contact ground.

6)

Retighten the (4) 5/8” nuts to 170 ft. lbs.

7) Remove blocks from under skid shoes.

8)

Adjust the skid shoes 1”- 2” from ground

to prevent scalping by means of the 1/2”

carriage bolts and the 1/2” pivot bolts.

9)

Refer to page 4-5 in Section 4 for an

illustrated parts listing.

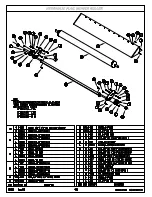

Knife Reversal or Replacement:

When the knives become dull, they should be

reversed to extend the usable life. When both sides

of the knives become dull, the set must be replaced.

Always replace knives as a set (2), either when

broken or dull. If a set of knives is replaced, the set

on the opposite side of rotor must be replaced to

maintain the balance. (The knife mounts are

staggered and no set is directly across from another.

If the 3rd set of knives is replaced on one side,

replace 3rd set on opposite side, etc.).

1)

Refer to page 4-4 in Section 4 for an illustrated

parts listing.

2)

Remove the 9/16” standard nut , (2) flat

washers, the 9/16” bolt, and the set (2) of

knives.

3)

Install new knives or reversed set. (The bolt

must be inserted through the knife mount from

the left side in

in order for the nut to be tightened by rotation).

4) Make certain the bolt is forced to the outside of

the knife mount loop.

Содержание 48MH

Страница 4: ......

Страница 6: ......

Страница 9: ...Section 1 Safety ...

Страница 16: ......

Страница 17: ...Section 2 Operating ...

Страница 20: ......

Страница 21: ...Section 3 Maintenance ...

Страница 29: ...Section 4 Service Parts ...

Страница 30: ......

Страница 33: ......

Страница 34: ......

Страница 35: ......

Страница 36: ......

Страница 37: ......

Страница 38: ......

Страница 39: ......

Страница 40: ......

Страница 41: ......

Страница 42: ......

Страница 43: ......

Страница 44: ......

Страница 45: ......